AI in Manufacturing: 10 Ways AI Is Changing the Manufacturing Industry

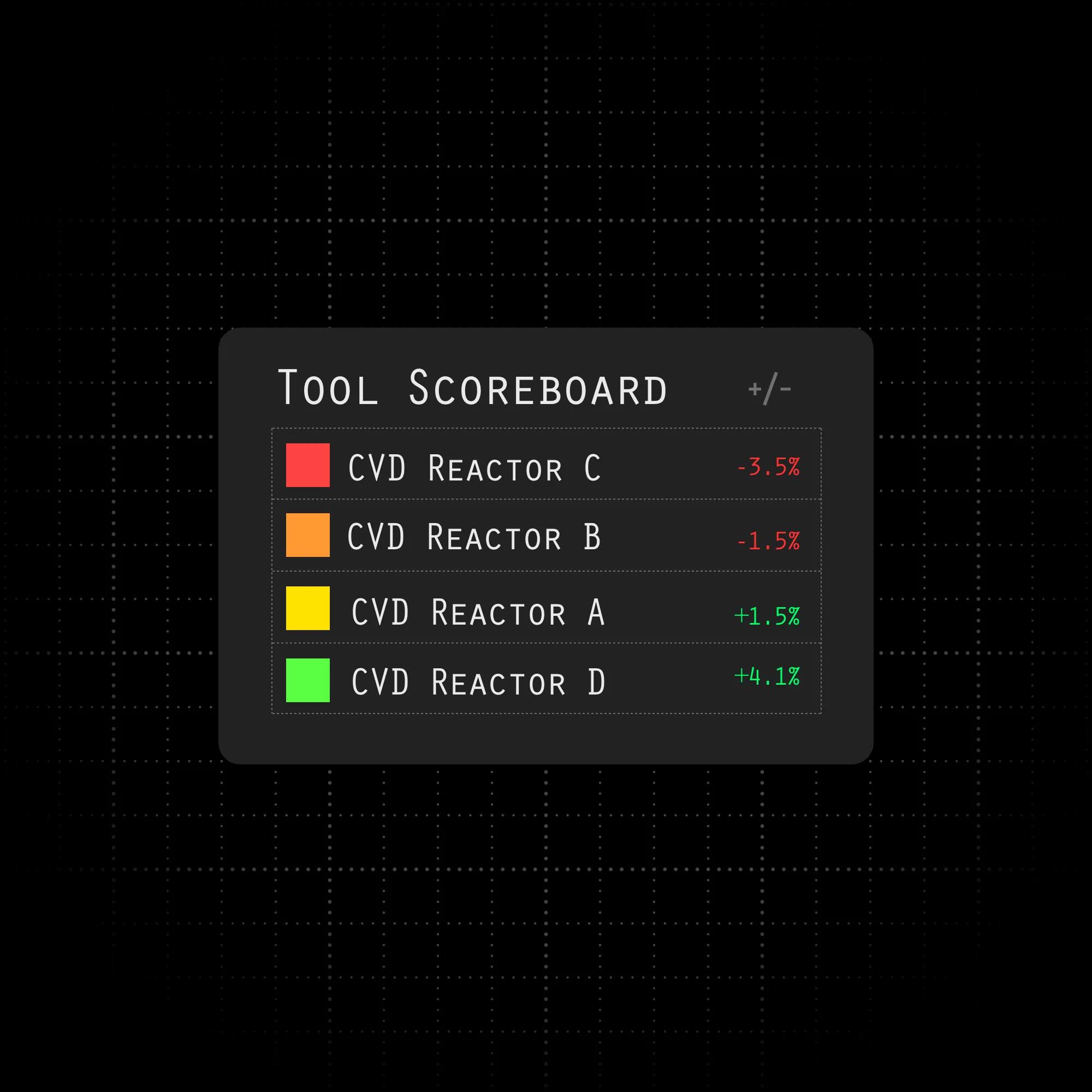

nControl uses AI process automation to calibrate your factory's data to drive performance, optimize operations, reduce downtime, and boost productivity across the board.

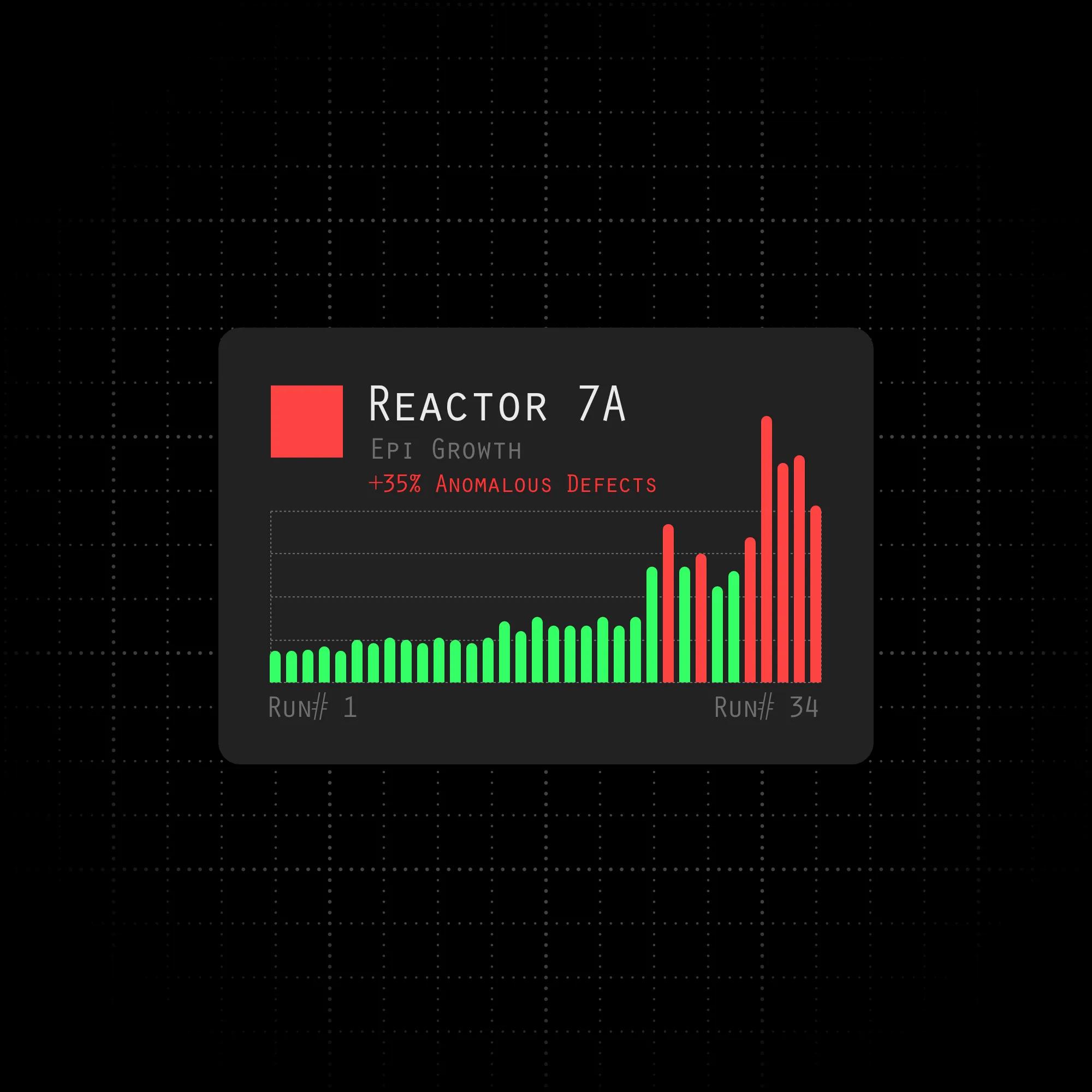

Combine inspection and AI-driven process control to drive up yields.

Integrate factory sensor and automation data to track, monitor, and improve yields and performance.

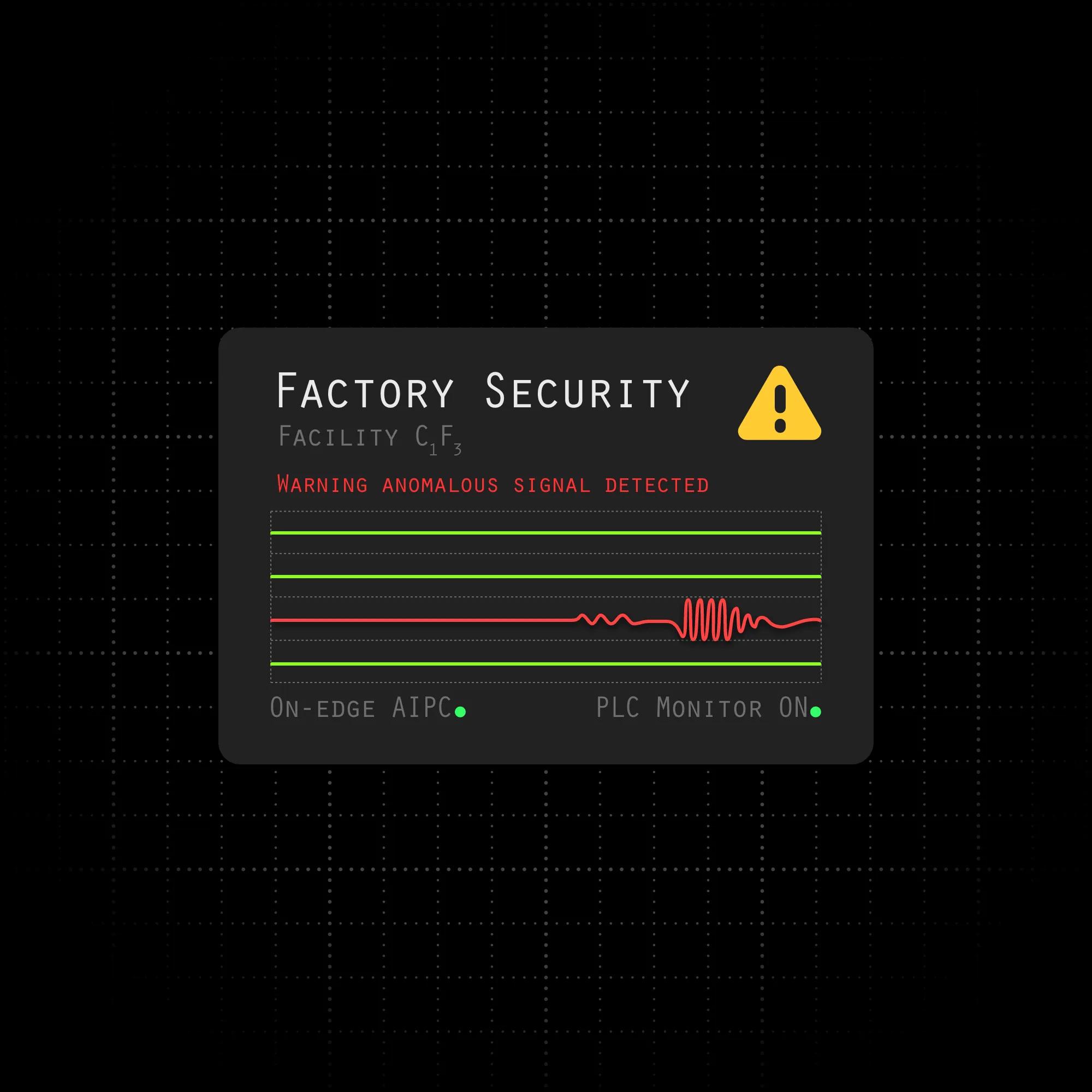

Utilize sensor data across your facility to monitor production, predict threats, and protect your processes.

Use deep learning to get KPI predictions, anomalous activity alerts, and autonomous control so the factory automatically adapts to increase yields and avoid malfunctions.

Accelerate process development from biologics to small molecules, wearable diagnostics to medical imaging devices.

Boost yields across chemical processing and advanced materials manufacturing.

Advance your EV transition with process control solutions for batteries, semiconductors, and advanced materials.

Push process performance to new heights for any wafer or device.

AI process automation is the use of artificial intelligence to monitor, adjust, and optimize manufacturing operations in real time. By continuously learning from data, AI enhances semiconductor production by identifying defects, predicting failures, and ensuring consistent quality.

AI automates processes by using machine learning algorithms to analyze real-time data, detect inefficiencies, and make automatic adjustments without human intervention. In semiconductor manufacturing, AI process automation fine-tunes production settings to reduce defects, improve yields, and minimize downtime.

AI boosts semiconductor yields by detecting anomalies, predicting wafer defects, and dynamically adjusting process parameters. With AI process automation, fabs can continuously refine manufacturing conditions, leading to higher output and fewer discarded chips.

AI enhances process improvement by analyzing production data to detect inefficiencies and make automated, precision-driven adjustments. AI process automation eliminates guesswork, ensuring semiconductor manufacturing runs at peak efficiency with minimal waste.

AI won’t replace robotic process automation (RPA), but it will enhance it by making automated systems smarter and more adaptable. AI process automation enables RPA to handle more complex decision-making, improving semiconductor manufacturing efficiency and accuracy.