What is Wafer-Level Packaging, and What Forms Does it Take?

Optimize process control with our generative AI system. nControl integrates factory sensor and automation data to track, monitor, and improve yields and performance.

Understand how different process variables affect performance metrics and discover adjustments that reduce defectivity.

Rapidly and automatically detect the root causes of process failures.

Accelerate manufacturing process development and scale up production by automatically optimizing process settings for new production contexts.

Schedule a personalized demo and walkthrough with one of our product experts.

The anomaly detection capabilities nControl offered to us were highly effective in streamlining and refining the site’s chemical processes.

Anonymous

Protected

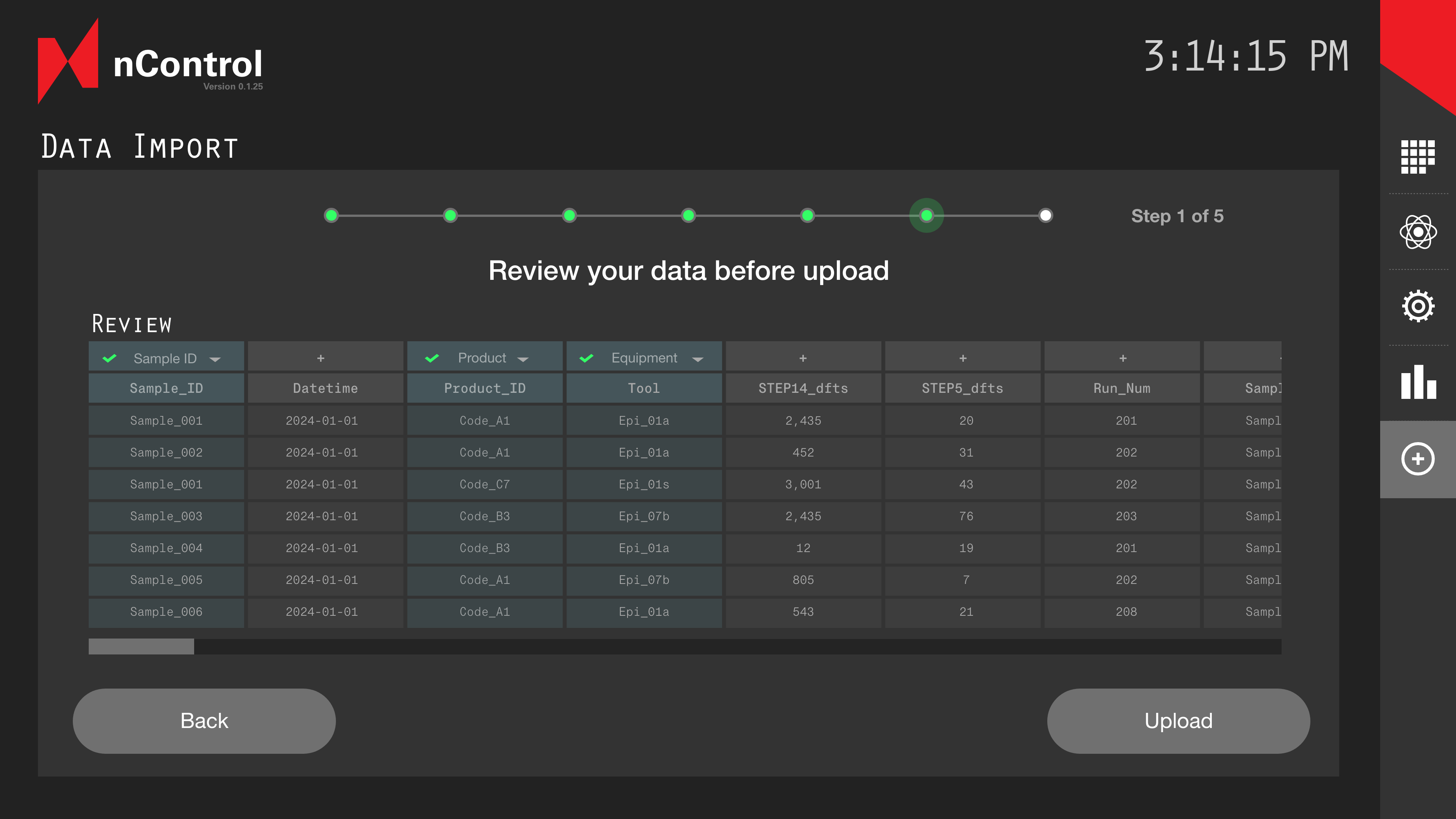

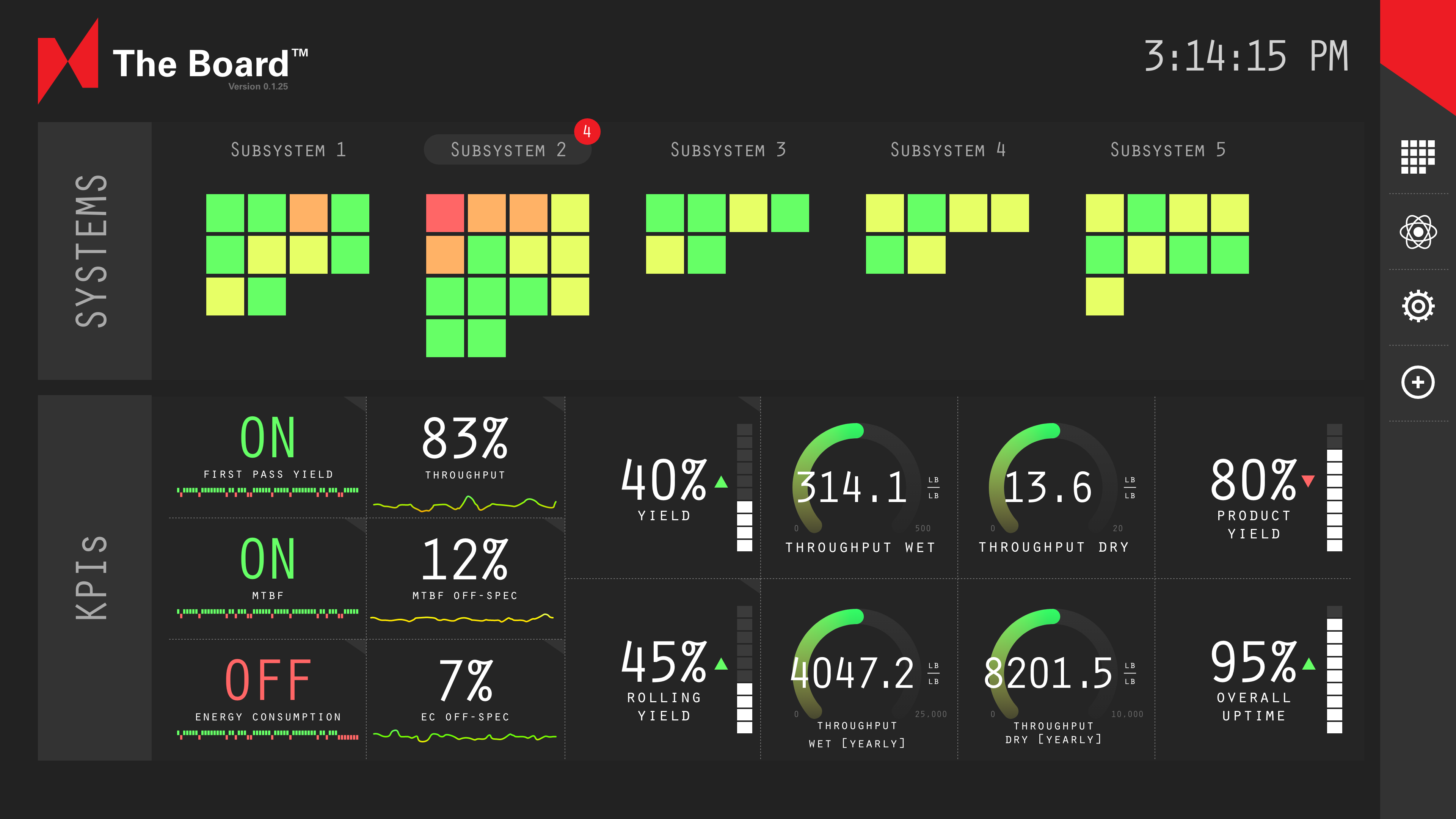

Integrate data from diverse sources across the production process.

Combine process logs, sensor readings, and quality measurements into a single, chronologically organized database that shows how each batch evolves from start to finish.

Track trends, compare performance between sites and processes, and drill down on particular batches or equipment components.

On-premise edge computing ensures that your data always stays with you.

Our integrations make it easy to ingest data from leading PLC brands, protocols such as SECS‑GEM, or industrial databases.

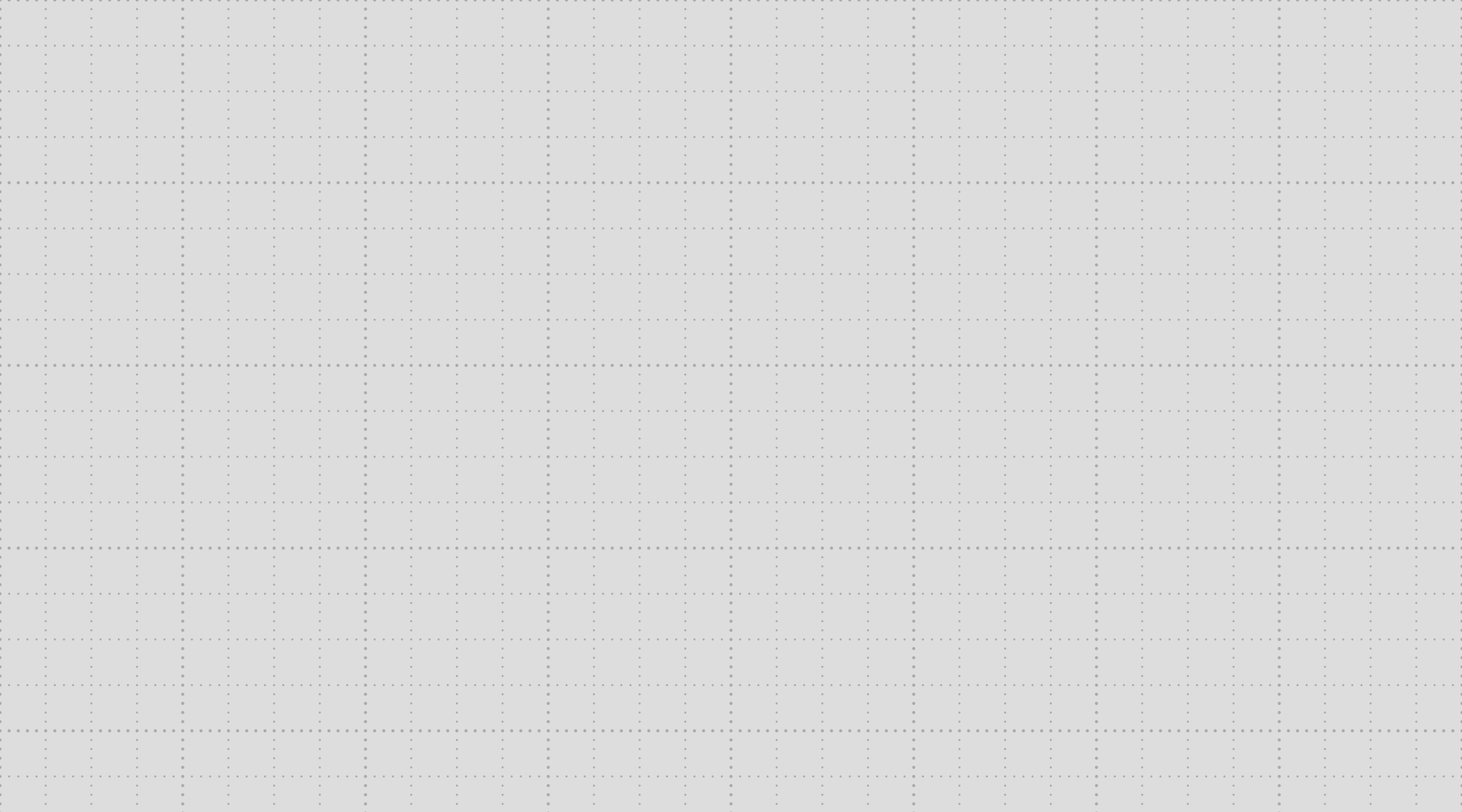

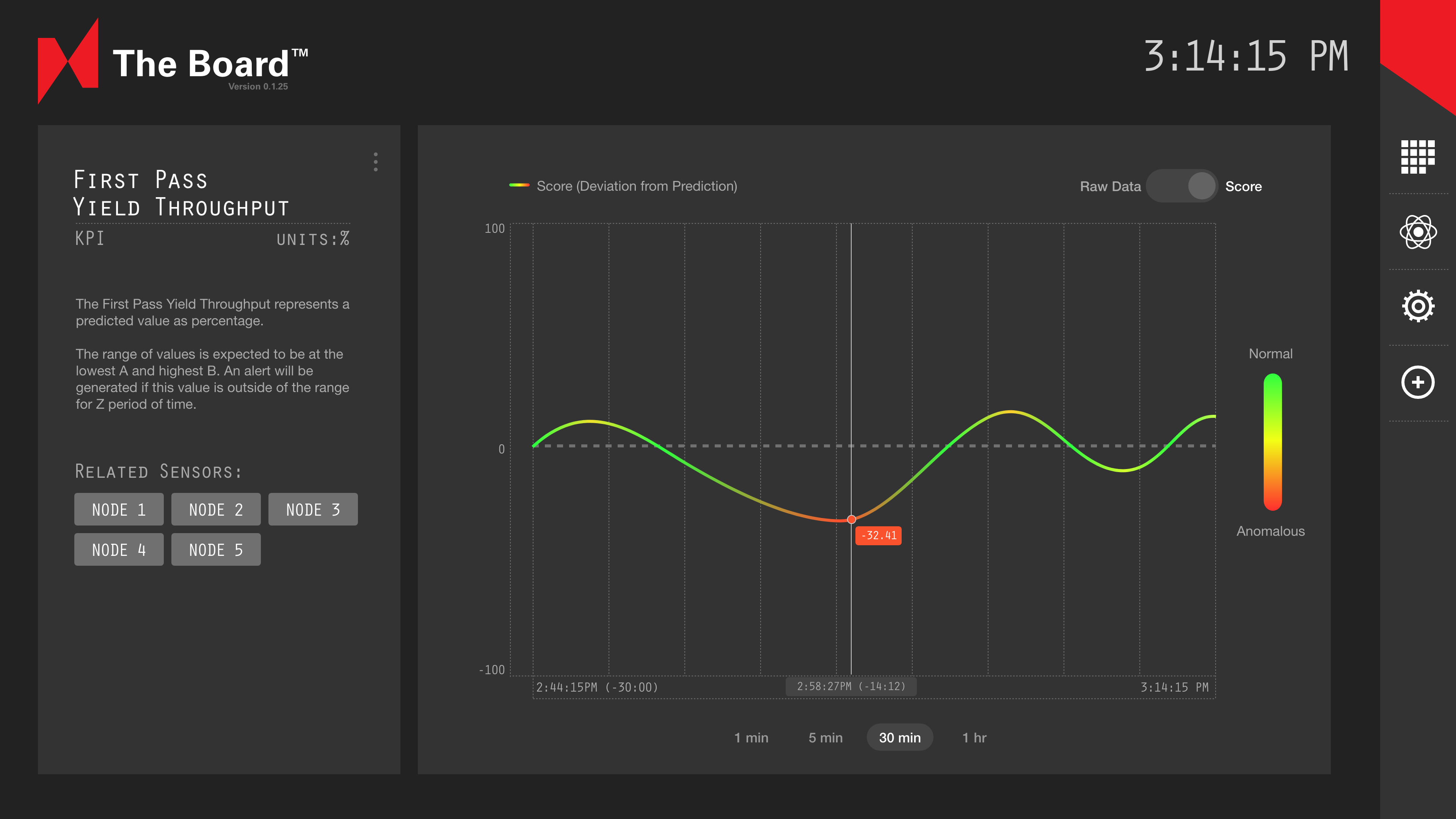

Real-time process monitoring for early detection of production problems.

nControl can be installed while your factory is operating, enabling a smooth transition to Industry 4.0.

nControl monitors for anomalous patterns in process data. So it can catch problems before traditional alarms go off — without wasting operators’ time flagging routine or transient harmless changes.

nControl analyzes process data leading up to an incident to pinpoint which parts of the process may have been responsible.

nControl predicts quality and yield metrics in real time — so you can anticipate how a product will perform, even before it’s finished.

The next generation of process control: processes that optimize themselves to achieve better performance.

nControl models learn flexibly from data, generating process adjustments predicted to improve quality and productivity KPIs.

Rescue quality from unexpected perturbations by adjusting the process in real time.

Take the trial-and-error out of R&D by automating the search for the best-performing process.

nSpec caters to a wide range of customers with ease — in R&D, high-volume manufacturing, semiconductors, healthcare, and beyond.

nSpec software comes standard across all systems, decreasing the time needed to find device-killing defects.

nTelligence is able to identify, classify, and assign causality to various features of interest.

nSpec comes with various footprints to meet the facility requirements of many production environments.

Pairing process engineering teams with realtime AI assistance lifts production to new heights.