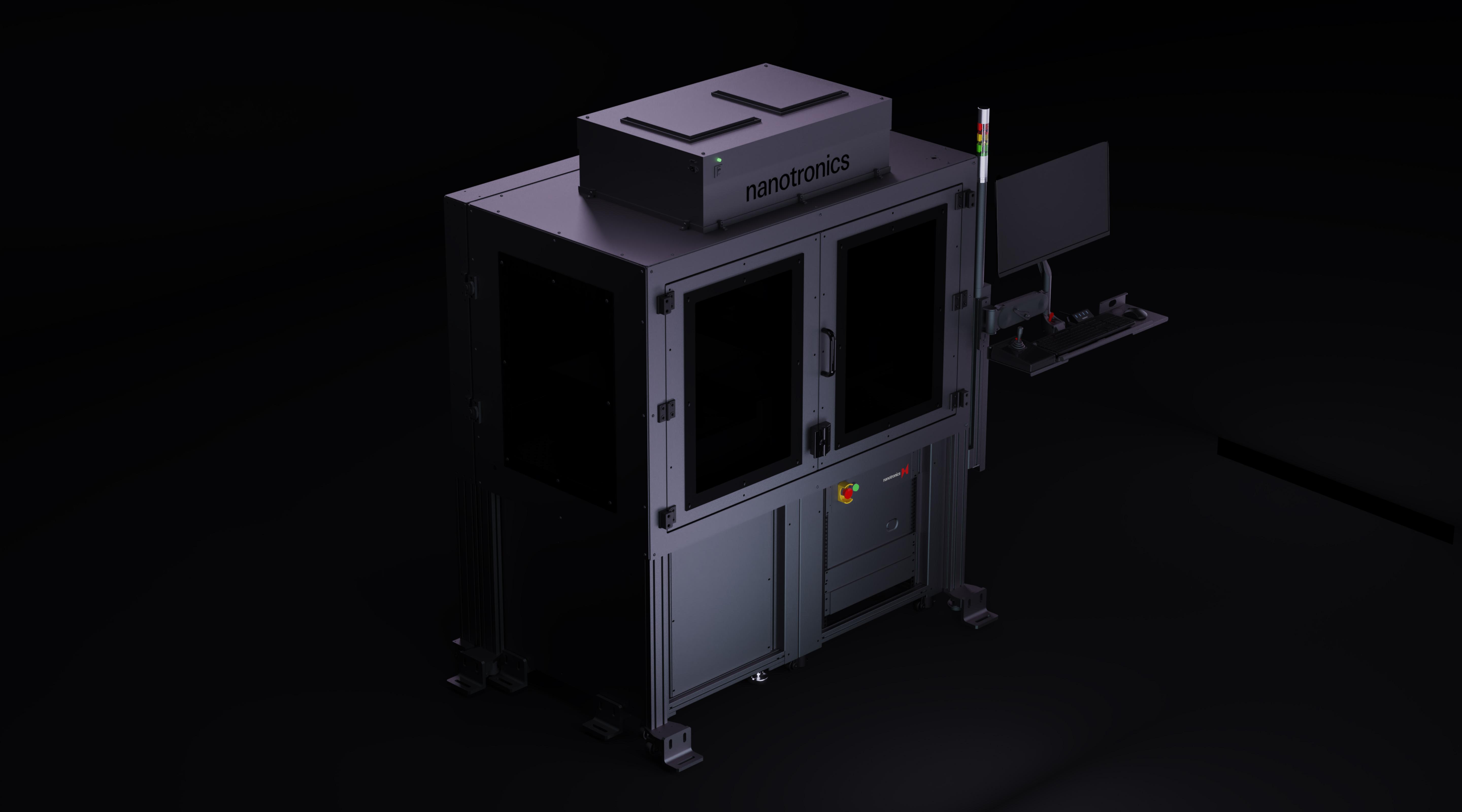

nSpecPRISM

The nSpec PRISM offers a complete solution for compound semiconductor front-end wafer manufacturing.

Photoluminescence inspection for front-end wafer manufacturing

Process agnostic

Gather valuable data points throughout production of compound semiconductors from unpolished substrates to epitaxy and device manufacturing.

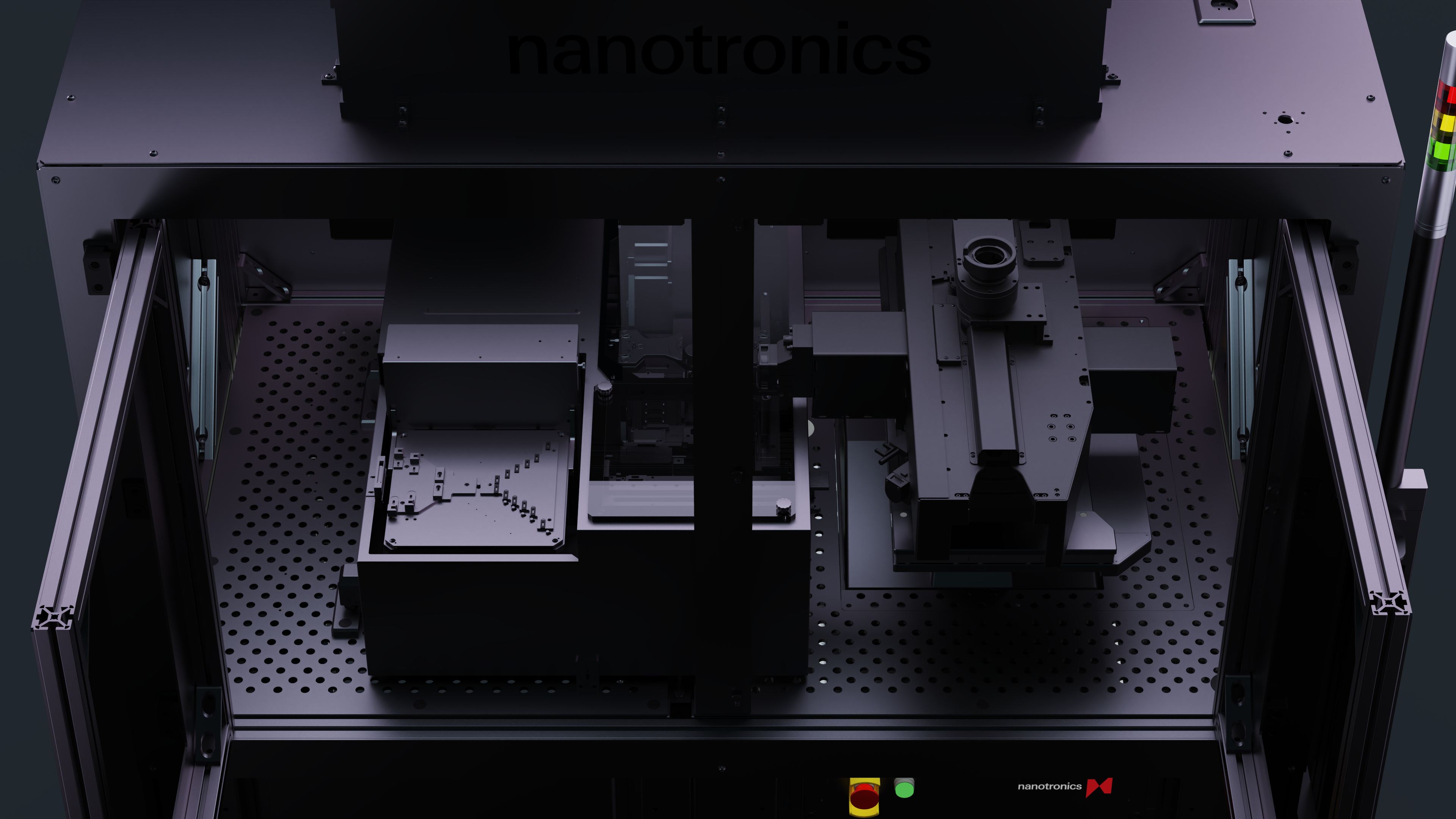

Advanced illumination

The PRISM system incorporates a variety of illumination wavelengths to image a variety of materials and classify multiple defect types.

Speak with one of our product experts

Schedule a personalized demo and learn how Nanotronics can help your operations.

We have been using nSpec systems for the mapping of micropipes and dislocations in SiC wafers. It is a critical tool for our manufacturing process control and for the development of high quality SiC substrates.

Anonymous

Quality Manager

The ideal system for compound semiconductors

Flexible software

User-friendly software makes configuring recipes simple. As needs evolve, recipes are easily saved and modified.

Robust hardware

The nSpec PRISM can manage various sample form factors and uses Nanotronics' custom illuminator to inspect a wide range of materials.

Powered by Nanotronics AI

nTelligence is trained to identify early process defects before scaling to high-volume manufacturing.

Various lighting modalities

The illuminator enables operators to utilize existing imaging modalities while adding UV and IR Illumination to inspection processes.

Find device-killing defects.

System

Weight

363 kg

Dimensions (W x D x H)

236 cm x 157 cm x 194 cm

Min. Vacuum Requirement

-21 in. Hg (-70 kPa)

Power Supply

208—240 VAC, 15A, 50—60 Hz

Optics

Illumination Modes

Brightfield, Darkfield, Automated DIC (Nomarski), Ultraviolet Photoluminescence

Light Source

White light LED, Reflected UV LED (other options available)

Objectives

5x (included), 1.25x, 2x, 2.5x, 10x, 20x, 50x

Objective Turret

5‑position, User‑selectable

Stage

Travel, typical

200 mm X and Y directions

Positioning

Linear servo motors with closed‑loop encoders (50 nm resolution)

Repeatability

+/- 0.5 µm

Travel Flatness

30 µm

Centered Load Capacity

2.27 kg

Wafer Loader

Cassette

25 wafers / cassette, single Standard H‑Bar

Standard Wafer Sizes

50, 75, 100, 125, 150, and 200 mm

Wafer Alignment

Automatic by notch or flat

Options

Supported Protocols

SECS/GEM

Illumination

Transmitted light with automated polarizer

Filters

12‑position filter wheel

Enclosure

CleanCube (included)

Handling

OCR (frontside or backside), Ergonomic cassette loader, Sample specific fixtures

Machine learning

Offline workstation, nTelligence™

Automate inspection across your R&D and production lines

Automated Optical Inspection (AOI) is one of the most efficient forms of device inspection, but it is typically limited by resolution. Nanotronics AI detection algorithms overcome this and detect defects that would otherwise go unnoticed.