Silicon Carbide

Power electronics

Power electronics

Identifying critical defects in silicon carbide

Robust hardware

Nanotronics has designed configurations specific for use with SiC substrate, epi, and devices.

Transmitted light and cross polarized illumination

nSpec can accurately detect and classify subtle crystallographic defects such as micropipes.

Recommended Product

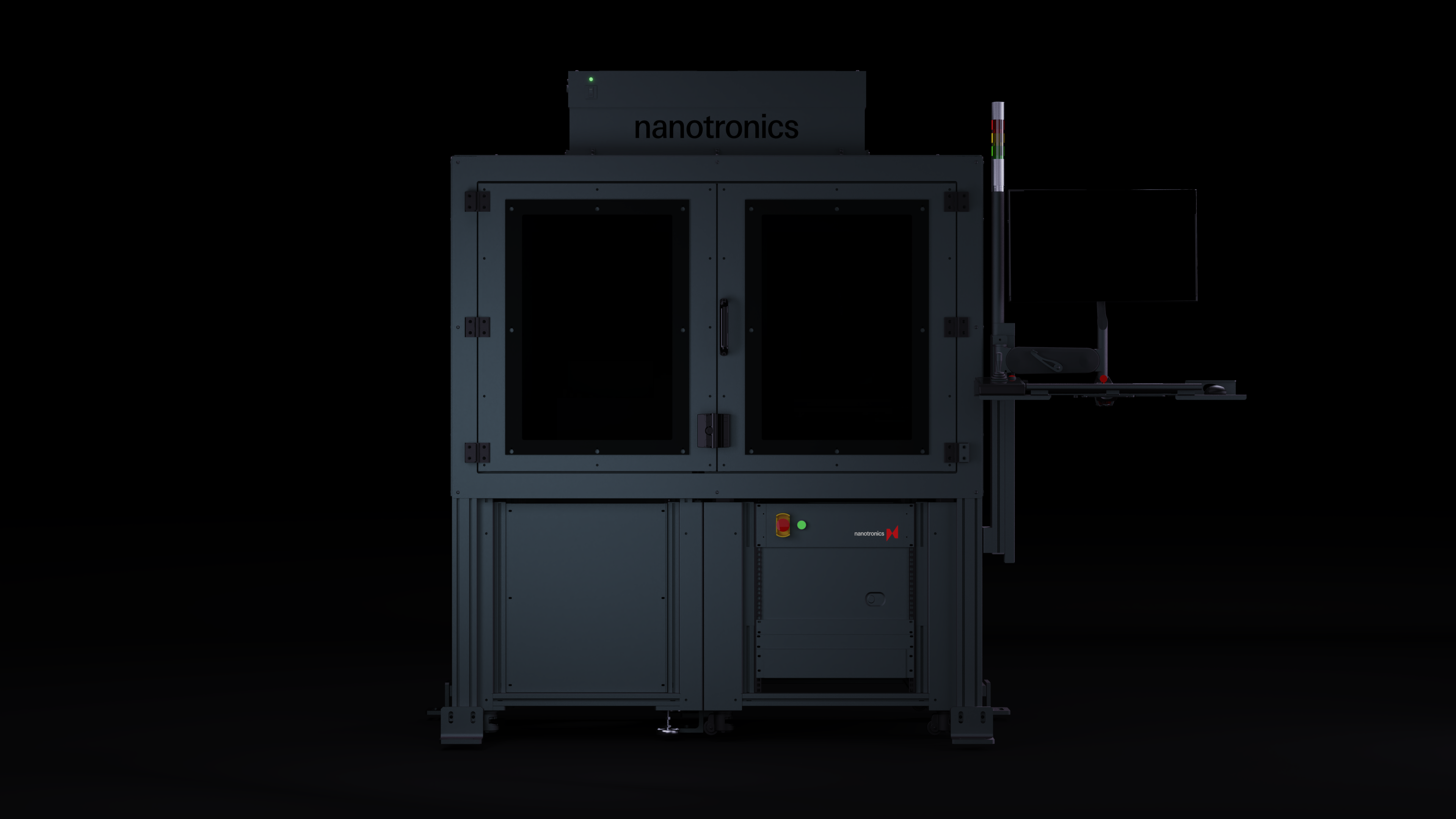

nSpecPRISM

The nSpec PRISM offers a complete solution for compound semiconductor front-end wafer production, from unpolished substrates to epitaxy and device manufacturing.

System highlights

Automatically detect and classify

Crystalline defects

nSpec can detect stacking faults and other crystalline defects in the bulk of the material.

Dislocations

On etched wafers, detect defect types by shape and provide counts, sizes, and locations for all defects, such as threading edge dislocations and threading screw dislocations.

Micropipes

Accurately detect and classify subtle crystallographic defects. covering virtually the full area of the wafer.

Gallium Nitride on Silicon Carbide

Grow gallium nitride epitaxy on silicon carbide substrate for your power electronics.

Detecting cracks

Differentiate between cracks and slip lines, a crucial step in improving GaN manufacturing.

Detecting slip lines

Slip lines are subsurface lines resulting from shear stress in the silicon substrate itself.

Lattice mismatch

Easily identify lattice mismatch and thermal stress from a difference in thermal expansion coefficients.

V-pit or inverted pyramids

Identify defects that will cause voltage leaks.