Indium Arsenide

High speed transistors

High speed transistors

Features

Identifying critical defects in indium arsenide

Our AI provides solutions

Train a pipeline specific to your defects.

Autofocus

Advanced autofocus algorithms determine an autofocus map to deliver precise results across batches.

Recommended Product

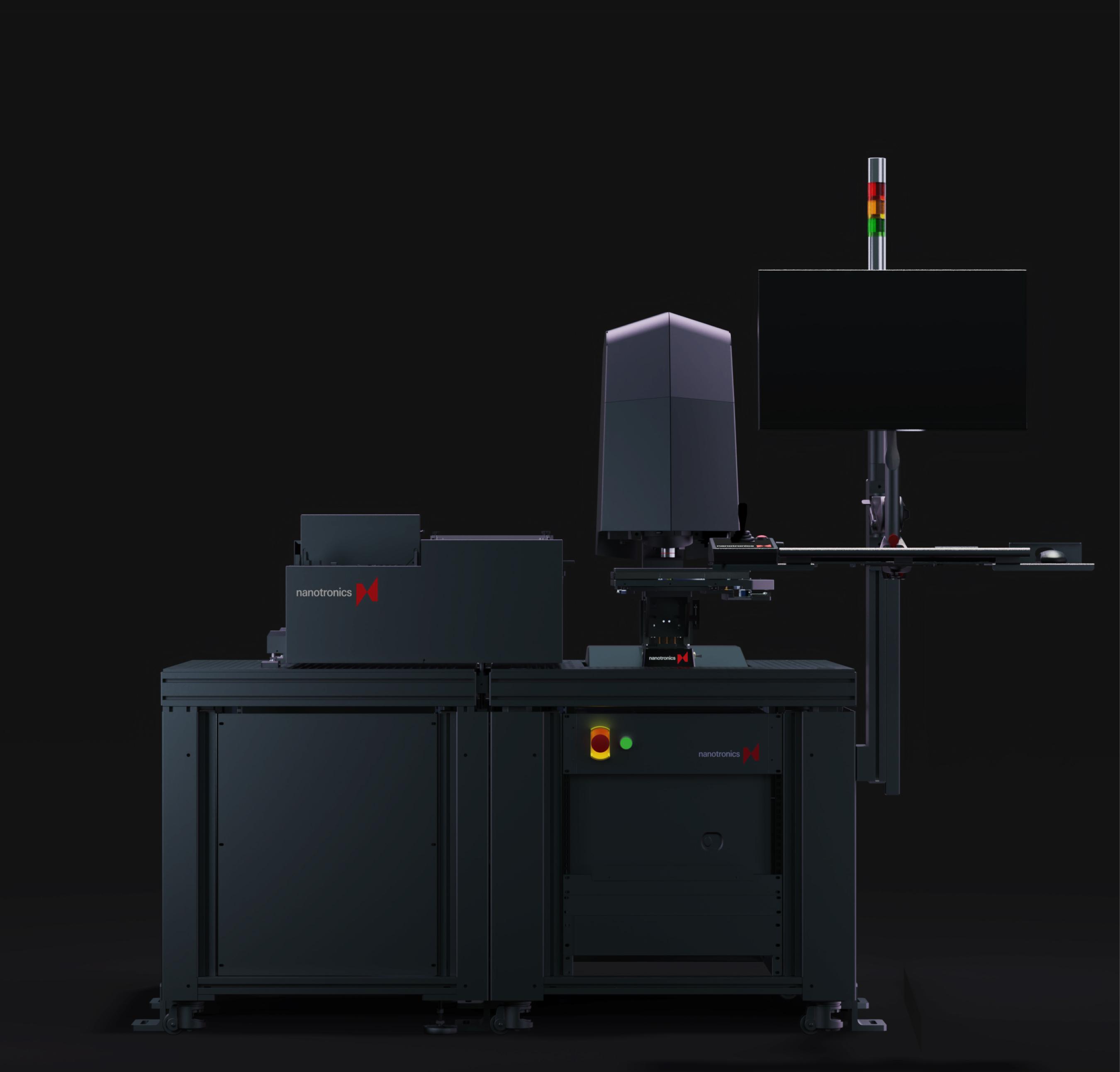

nSpecPS

The nSpec PS is highly flexible and detects defects in a variety of wafers, substrates, and materials.

System highlights

LoadingAutomated wafer loading

Max Wafer Size200 mm

Scan Resolution0.9 µm/pixel (w/ 5x objective)

Benefits

Defect types

Dislocations

Detect defect types by shape and provide counts, sizes, and locations for all defects such as edge dislocations and screw dislocations.

Surface defects

Surface imperfections can affect the quality of subsequent layers deposited on the wafer.

Surface roughness

Determine surface roughness or haze to prevent non-uniform surfaces in subsequent processing steps.

Industries

Our solutions are tailored to meet the unique challenges and demands of each sector.

Downloads

Contact Us