Copilot

Expedite root cause analysis with AI insights to drive up yields.

Find anomalies faster

AI-driven software and hardware analyze metrology and MES data to detect subtle process changes, enabling quicker corrective actions. Compare resources to optimize production and improve efficiency.

Expedite excursions

Identify bottlenecks and prevent costly process excursions by monitoring equipment performance alongside production data, reducing downtime and improving throughput.

MES & inspection insights

Combine MES and inspection data with AI models to gain actionable insights, speed up root cause analysis, and optimize yield and process control.

Learn how Nanotronics can help your manufacturing

Schedule a personalized demo and walkthrough with one of our product experts.

What our team could not discover in 6 months was identified by your AI within a week of installation.

Principal Scientist

Discover root cause.

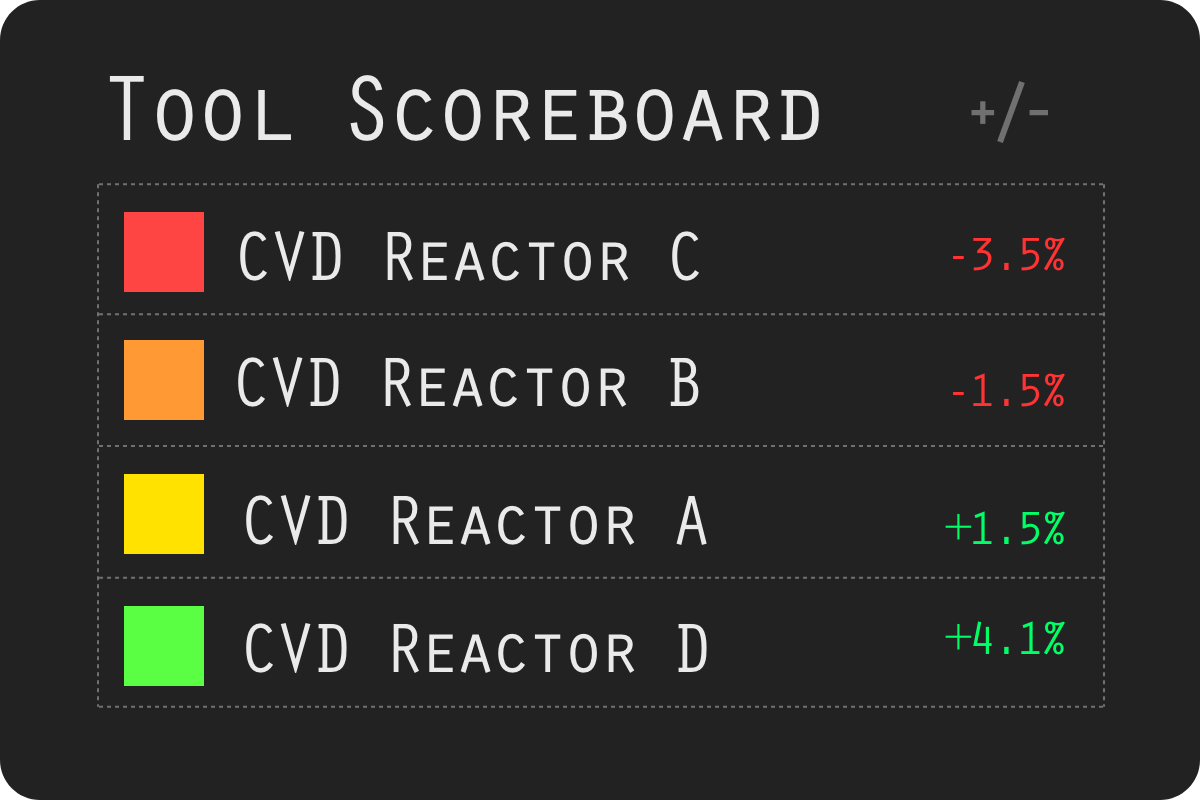

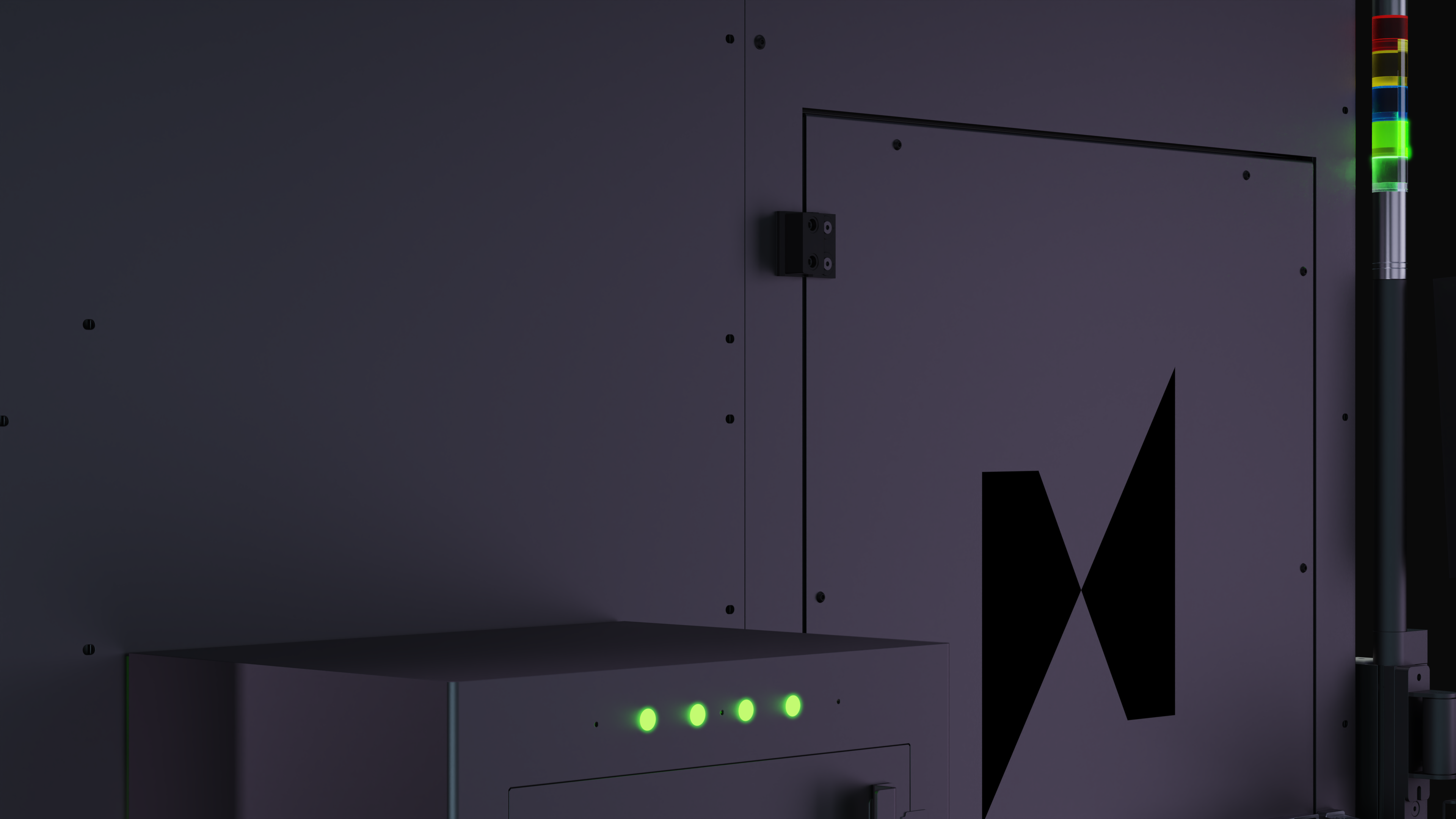

Copilot dashboard shows resource anomalies in realtime.

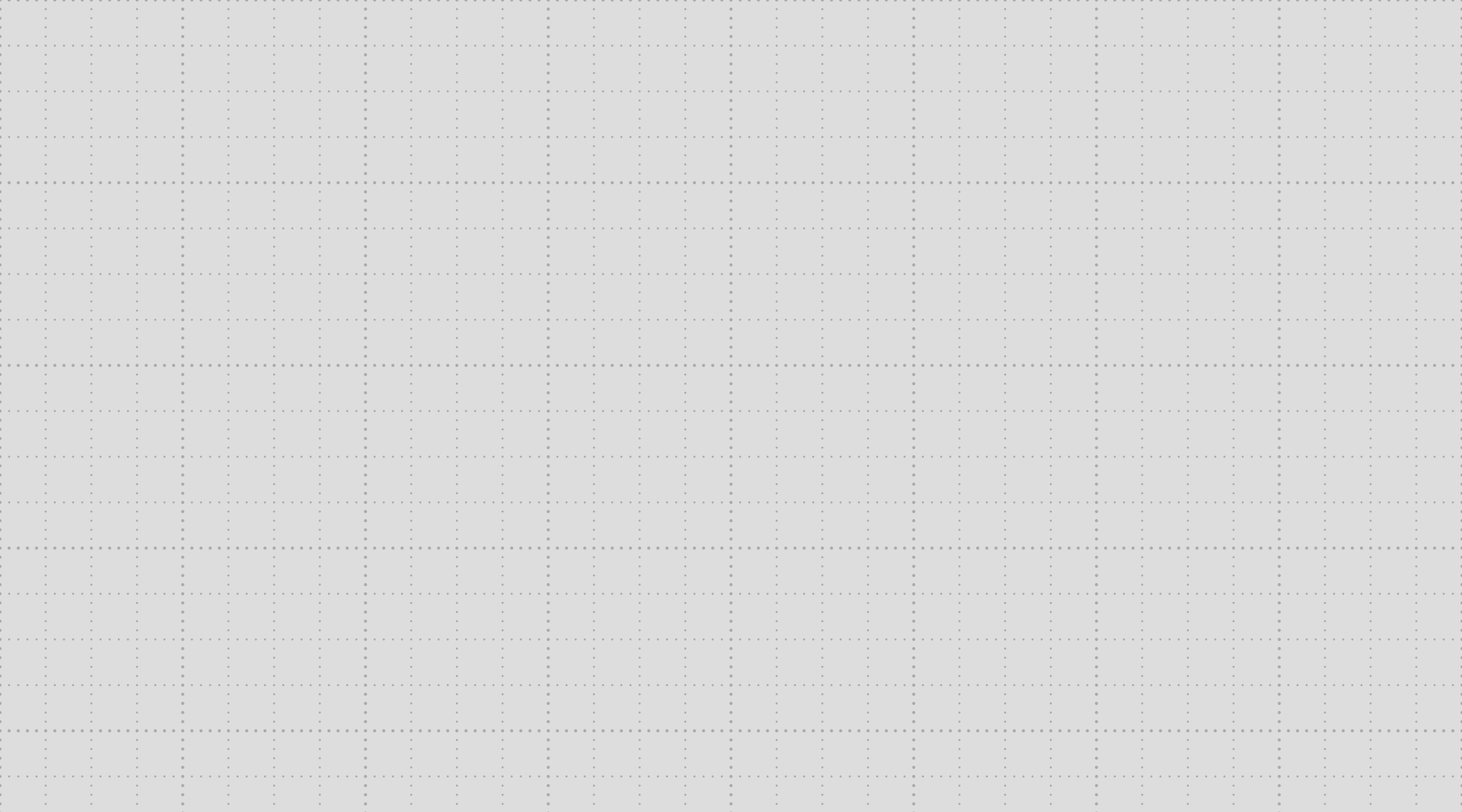

Tool scoreboard

Identify resources in your production that are responsible for or at risk of causing excursions.

Ready for production

Our AI models learn the relationships between process and quality outcomes so you can drive production to get better results.

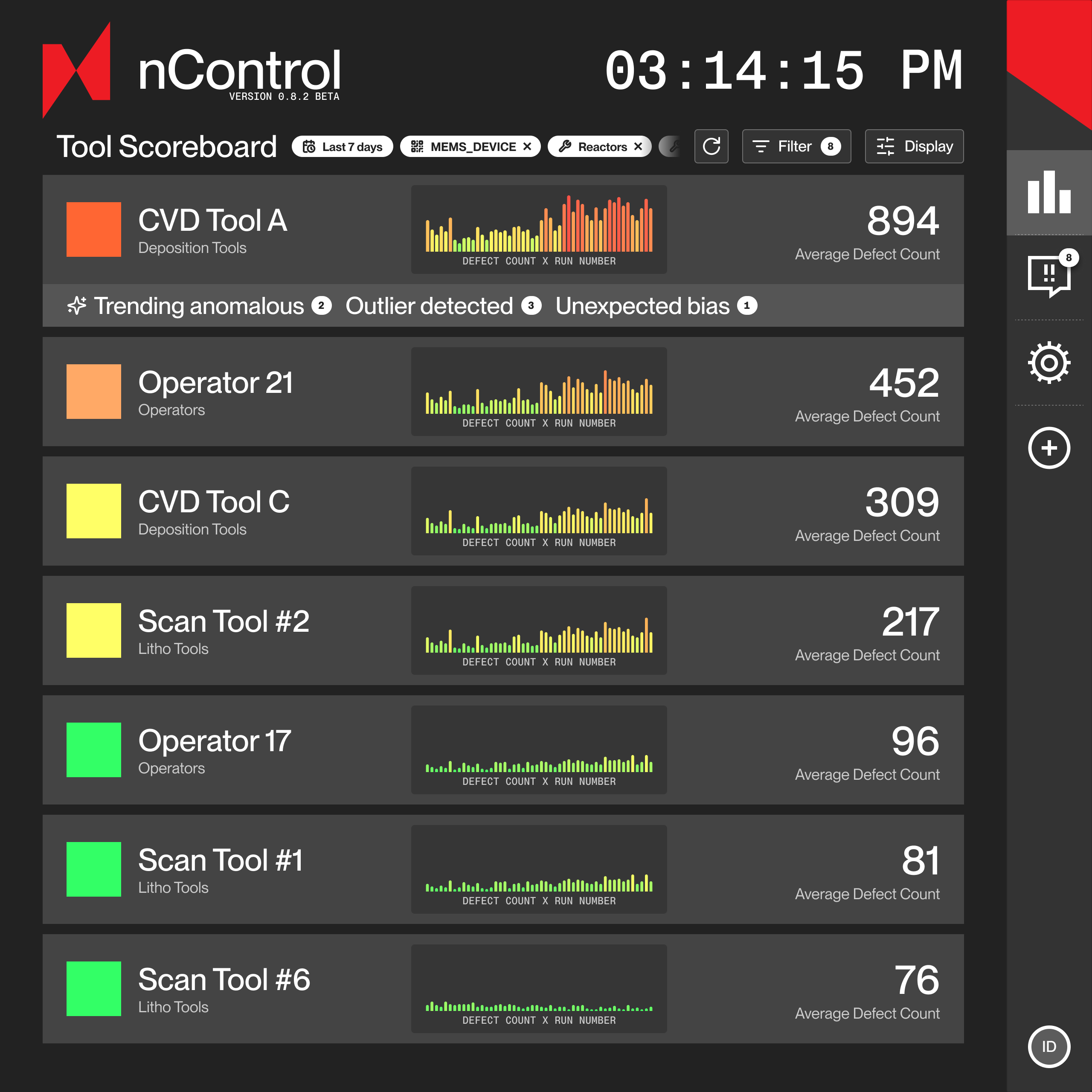

AI Insights.

Actionable notifications for process engineers and operators.

Ahead of schedule

Instantaneous insights on resource performance while browsing MES, metrology, and inspection data.

Intelligent alerts

Get insights when new data is manually or automatically ingested.

How it works

Understand process data, better

Copilot uses the latest AI models to analyze equipment performance, allowing process engineers to stay a step ahead of yield issues.

Get the most out of every resource

Compare resource performance across products and production lines to increase uptime and your bottom line.

Diagnose process problems

Analyze metrology and process data on each production run to localize the sources of quality variability.

Robust data analysis to identify key microdata points

Copilot enables process engineers to discover anomalies by autonomously ingesting various characterization data from production line MES systems and nSpec inspection data.

Tool scoreboard

Highlight any resource performing below expectations to help process engineers immediately identify the root cause of yield loss.

Product process overview

Visualize bottlenecks on a per-product basis to assist engineers and operators by circumventing any actively anomalous equipment.

Copilot assists manufacturers at any stage of manufacturing.

Copilot is used to assist R&D teams at high-volume production facilities during every step of the process.