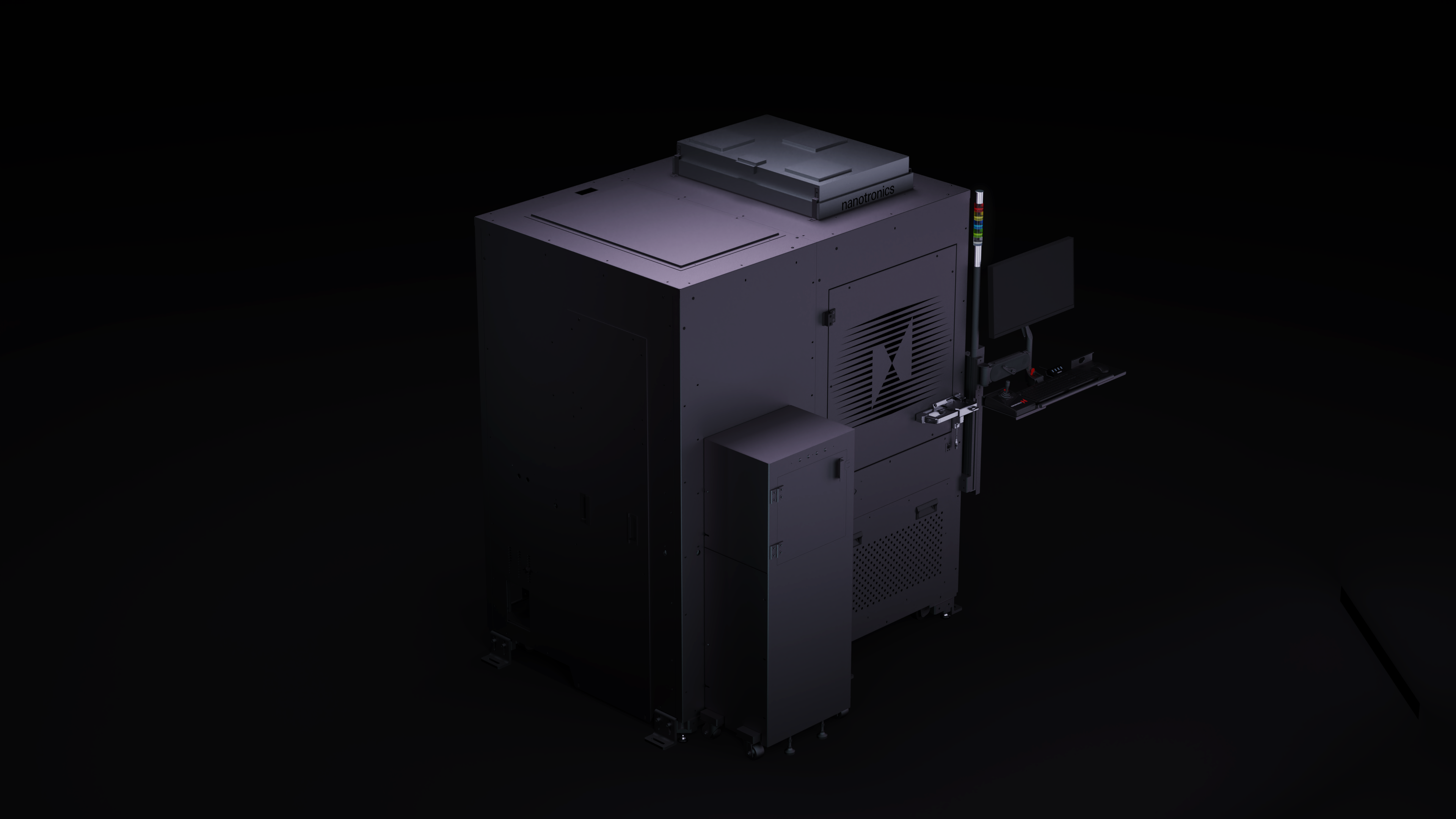

nSpecTURBO

The nSpec TURBO is the ideal system for fully automated high volume manufacturing environments.

Larger efficiency gains when scanning large format samples

Flexible handling

nSpec TURBO can be built with different configurations to accommodate multiple handling ports and a variety of sample sizes.

Reduce operational costs

nSpec TURBO allows operators to identify, classify, and assign causality to defects in order to prevent down-line issues.

Speak with one of our product experts

Schedule a personalized demo and learn how Nanotronics can help your operations.

nSpec satisfies a capability need for capturing high-resolution optical photos of wafers at intermediate stages of semiconductor process. nSpec is a versatile and dependable tool that can handle over one-hundred products.

Anonymous

Quality Scientist

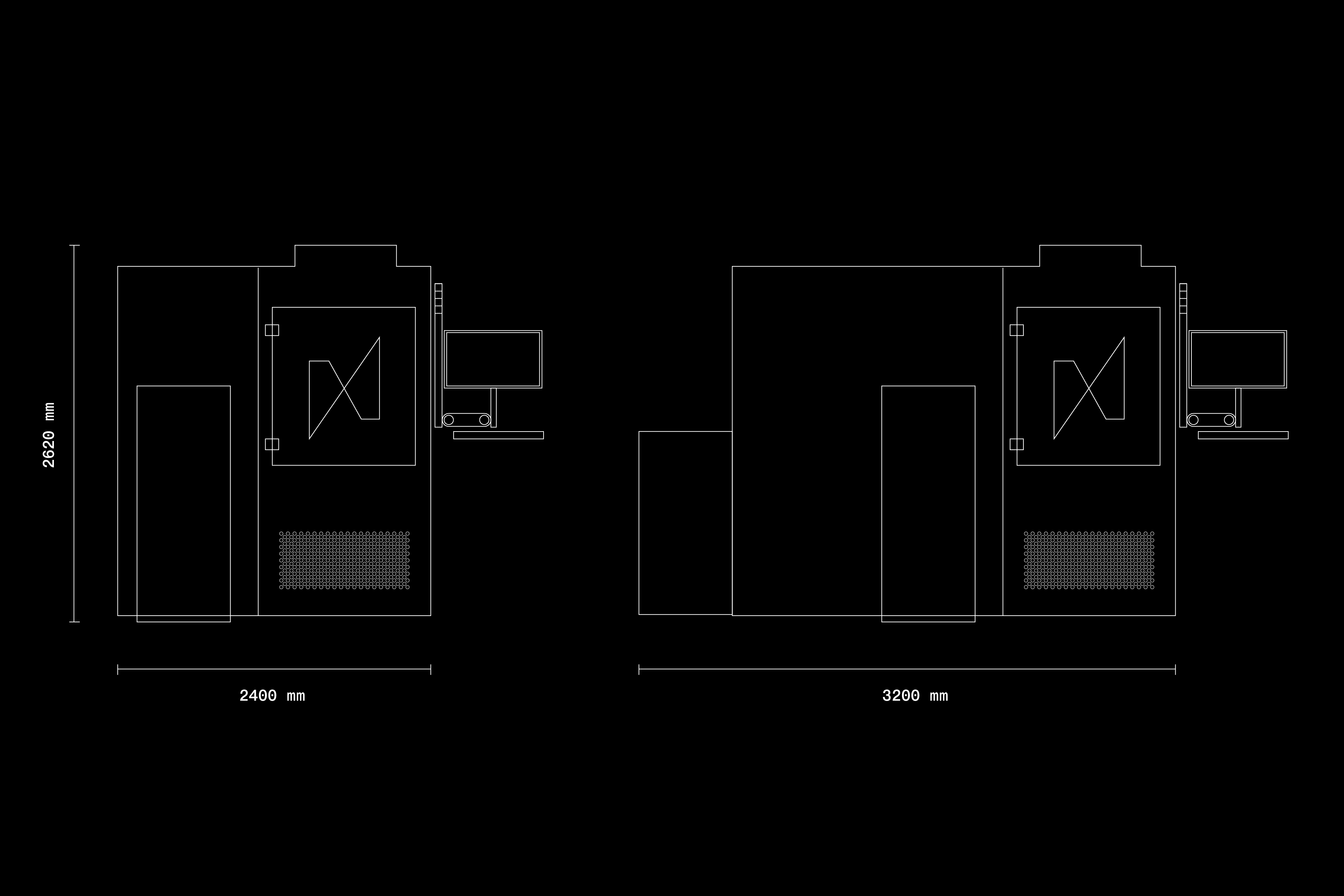

Fit your footprint

nSpec TURBO is available in two sizes to speed up quality control on production lines for 300mm sample sizes up to 650mm.

Find device-killing defects.

System

Weight

1200 kg

Dimensions (W x D x H)

240 cm x 194 cm x 262 cm

Min. Vacuum Requirement

-21 in. Hg (-70 kPa)

Power Supply

208—240 VAC, 15A, 50—60 Hz

Min. Clean Dry Air

60 PSI (415 kPa)

Optics

Illumination Modes

Brightfield, Darkfield, Automated DIC (Nomarski)

Light Source

White light LED (other options available)

Objectives

5x (included), 1.25x, 2x, 2.5x, 10x, 20x, 50x

Objective Turret

5‑position, User‑selectable

Stage

Travel, typical

350 mm X and Y directions

Positioning

Linear servo motors with closed‑loop encoders (50 nm resolution)

Repeatability

+/- 2 µm

Travel Flatness

20 µm

Centered Load Capacity

12.5 kg

Options

Supported Protocols

SECS/GEM, E-84 Interface

Illumination

Transmitted light with automated polarizer

Filters

12‑position filter wheel

Enclosure

CleanCube, Light Curtains

Handling

OCR (frontside or backside), Ergonomic cassette loader, Sample specific fixtures

Load Port

N2 Purge Load Port, 200 mm cassette adapter for Load Port

Machine learning

Offline workstation, nTelligence™, Gen‑V‑AI

Automate inspection across your R&D and production lines

Automated Optical Inspection (AOI) is one of the most efficient forms of device inspection, but it is typically limited by resolution. Nanotronics AI detection algorithms overcome this and detect defects that would otherwise go unnoticed.