Insights

Explained: The Inspection Process in Manufacturing

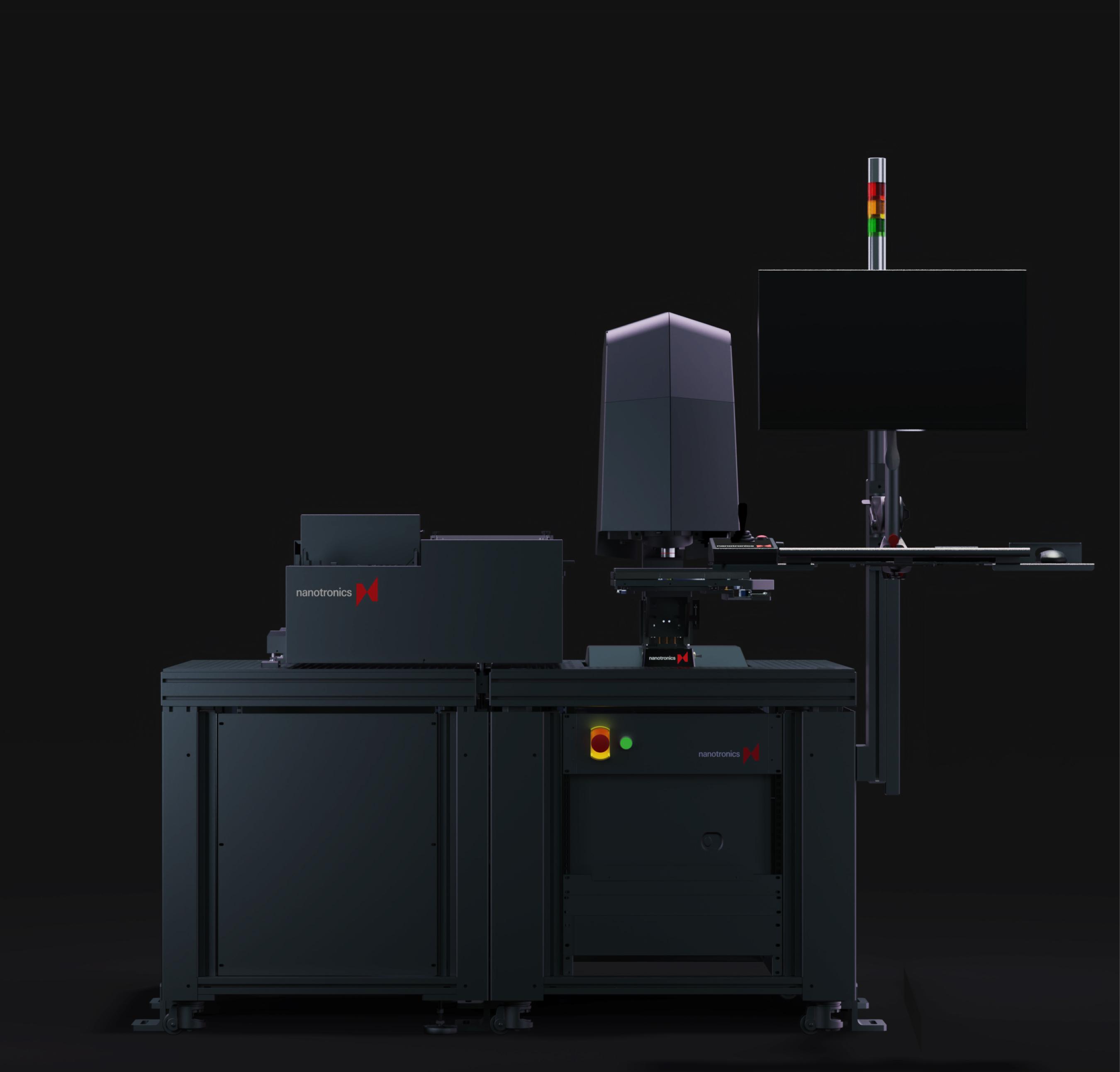

Perform rapid, full-sample defect detection and classification on substrate wafers.

Detect and classify crystal defects in substrate wafers with cross-polarized transmitted light.

Find device-killing defects in bare wafers prior to lithography and optimize future product layouts to maximize device yield.

Quickly analyze and measure subtle topographical features like surface roughness and haze.

Detect bevel defects, as well as edge chips and cracks, with wafer inspection that scans to the edges.

The nSpec PS is highly flexible and detects defects in a variety of wafers, substrates, and materials.