Companies and grassroots movements are exploring diverse mechanical solutions to the ventilator shortage –from Dyson’s pneumatic fan technology to MIT students’ low-cost DIY designs. But the simplest and most efficient solution may be found in your backyard shed and every commercial home-improvement store.

Contributed by Vadim Pinskiy, Damas Limoge, Parker Musselman, and James Hon

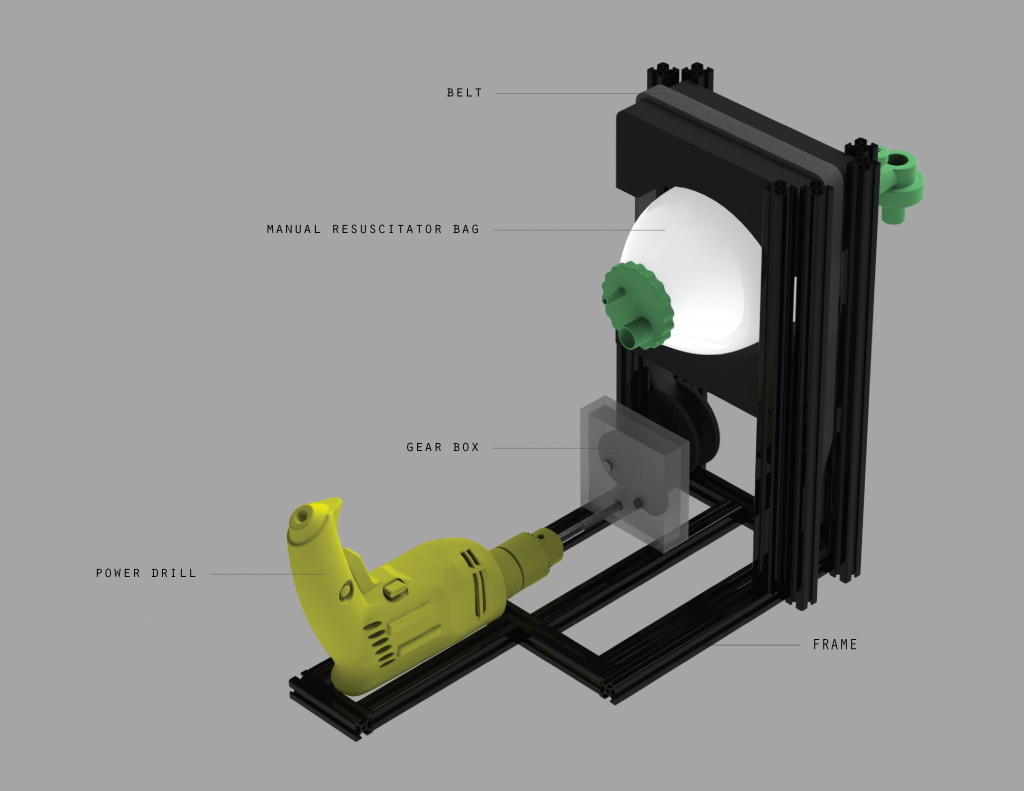

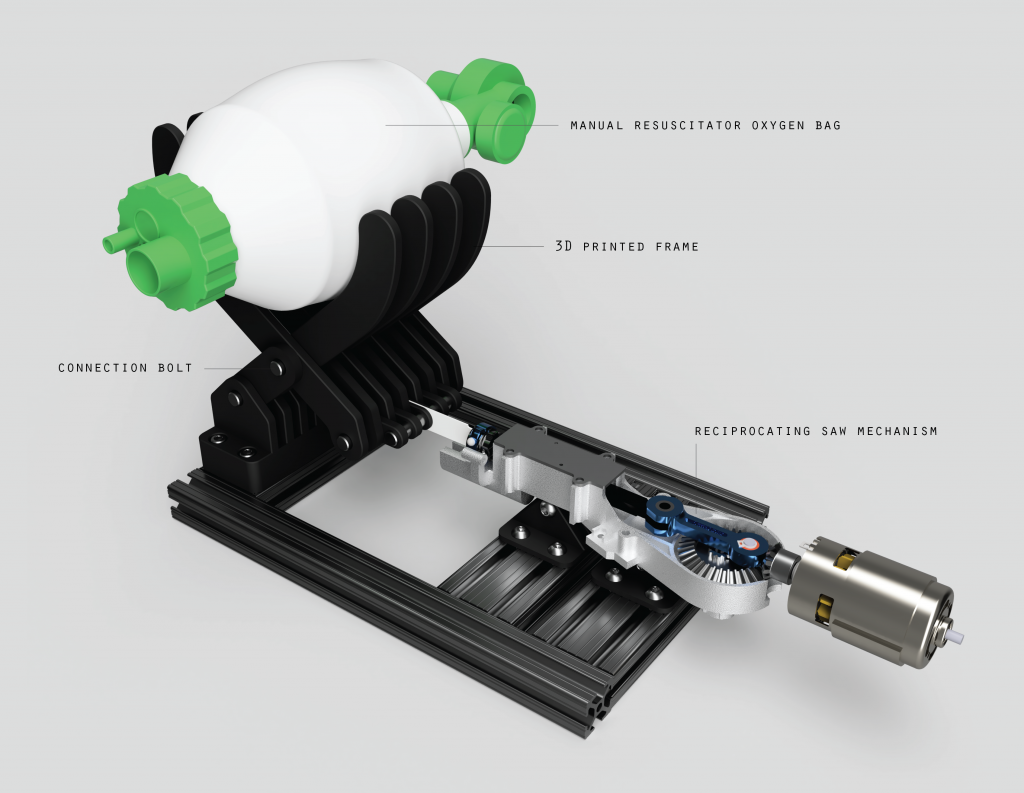

Nanotronics is currently prototyping ventilator designs by repurposing readily available components found in consumer home-improvement tools. Our current design uses hand drill and reciprocating saw parts from Dewalt, Craftsman, and other Stanley Black and Decker brands. Using off-the-shelf, low-cost components overcomes the need to develop complicated motor drive circuits.

Power tools have been perfected in demanding, regulated environments and produced in high volumes over decades. In addition, the needed components are incorporated into a package that is widely available for ~$100 or less. Many thousands already exist all over the United States in tool sheds and businesses. These can be disassembled and repurposed for usage in critical life saving devices.

The rotatory motion or torque of the motors used by power-tools have the mechanical force necessary to pump ventilators. These tools have some of the most sophisticated control logic, motors, and mechanical actuators commercially available. The added benefit is that high-end brands like Stanley Black and Decker have optimized power tools and high-capacity batteries. This means that these ventilators can be made portable and require only a swap of rechargeable batteries. This form makes it possible to deploy in the field hospitals and makeshift facilities that are becoming the norm in COVID-19 hotspots.

All ventilators use a central compression mechanism: an external airbag mimics the inhalation and exhalation of the lungs and diaphragm, using various forms of pulsation. Low-cost ventilators mimic the standard manual models present in most EMS kits, replacing the manual bag pulsation with a robotic mechanism. The rate of robotic pumping adjusts to the patient’s breathing. Such robotic mechanisms can run controllably and reliably for weeks to months on end.

A reciprocating saw uses a slider-crank mechanism. Its advanced controls allow for high torque and controlled stroke actuation. This mechanism can be directly adjusted to that of a patient’s breathing. The housing for the motors, actuators, and the ball valve can be 3D printed and quickly put together. These parts are fixed and can be modified into varying form factors and designs. We present one such design below. Though others can also be adapted.

Using readily available existing parts and materials to create new ventilator designs and bring them to scale distributes the means of manufacturing, speeds up production, and solves supply chain problems. Repurposing time-tested power tools delivers reliability and continuous operation that ventilators require.

To maximize the responsiveness of these ventilators, Nanotronics is combining practical AI control logic that it developed for semiconductors, chemical reagent processing, and 3D printing. The aim of AI usage is to enable greater control of the ventilator pulsation and to allow the physician and operator greater adjustment to benefit the patient. We are working with additional sensor and feedback methods that can be added for greater autonomous ventilation.

Nanotronics plans to use AI for the assembly of these systems to ensure that rapid production does not sacrifice Quality Control or result in harm done to the patient. Video based analytics can be used for on-the-fly assembly during rapid manual assembly and provide direct feedback to the assembler, revealing mistakes or corrections that need to be made. Every ventilator design such as this one is only of use if it can be assembled with high yield and field reliability. Available AI models help us to do that.

We are engaging our wider network of biomedical engineers, doctors, and the wider medical community to solicit feedback to improve function and incorporate known issues of commodity ventilators.

In parallel, Nanotronics envisions developing UVC-LED approaches that can be incorporated into these designs in the field, such that cleaning between patients and turnaround time can be fused into the design and prevent healthy patients from being infected during hospital stays.