A Chip Fab Business Grows in Brooklyn

CubeFabs are AI-operated, modular, prefabricated semiconductor fabs. These fabs are designed to be cost and time efficient to build, and reconfigurable for different materials and manufacturing processes.

Nanotronics is democratizing the opportunity to own and operate a semiconductor fab.

Learn morePre-fab architecture sets a new standard for factory build times and allows site owners to expand capacity with additional fabs.

CubeFabs is run on our proprietary AI process control, which allows us to scale materials that have traditionally been difficult to work with because of high defectivity. We will start by scaling Gallium Oxide, a material that has significant efficiency improvements over silicon, allowing for greater power efficiency in data centers and EV stations.

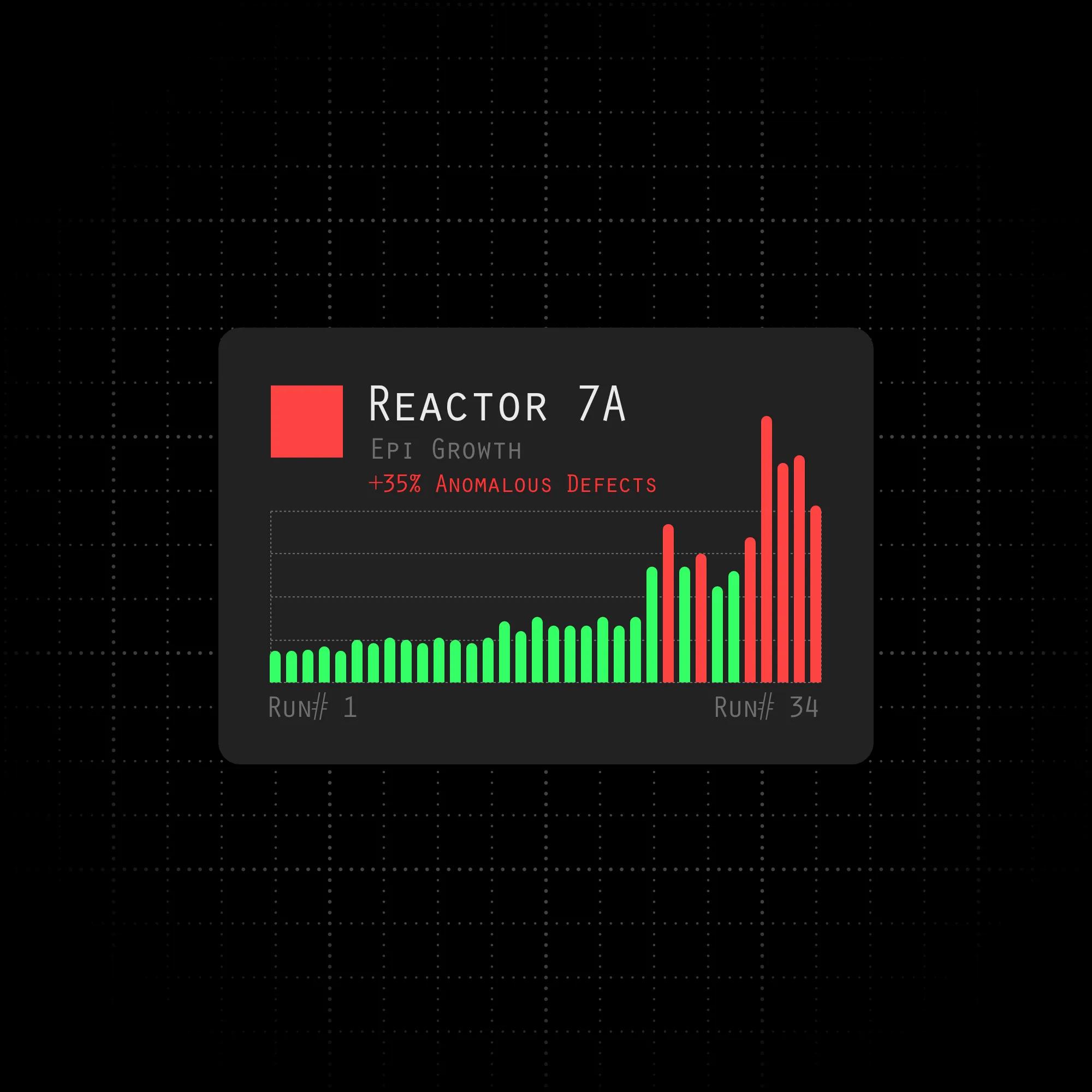

CubeFabs can monitor production and self-improve in real time. Our patented AI platform, nControl™, automates, monitors, and corrects highly complex manufacturing processes in real-time.

Each deployment follows local guidelines and regulations. Because the materials being produced are efficient, few resources are needed and very little waste is produced.

Designing a semiconductor fabrication facility with easy access to local greenery is healthy for the engineers and the ecosystem.

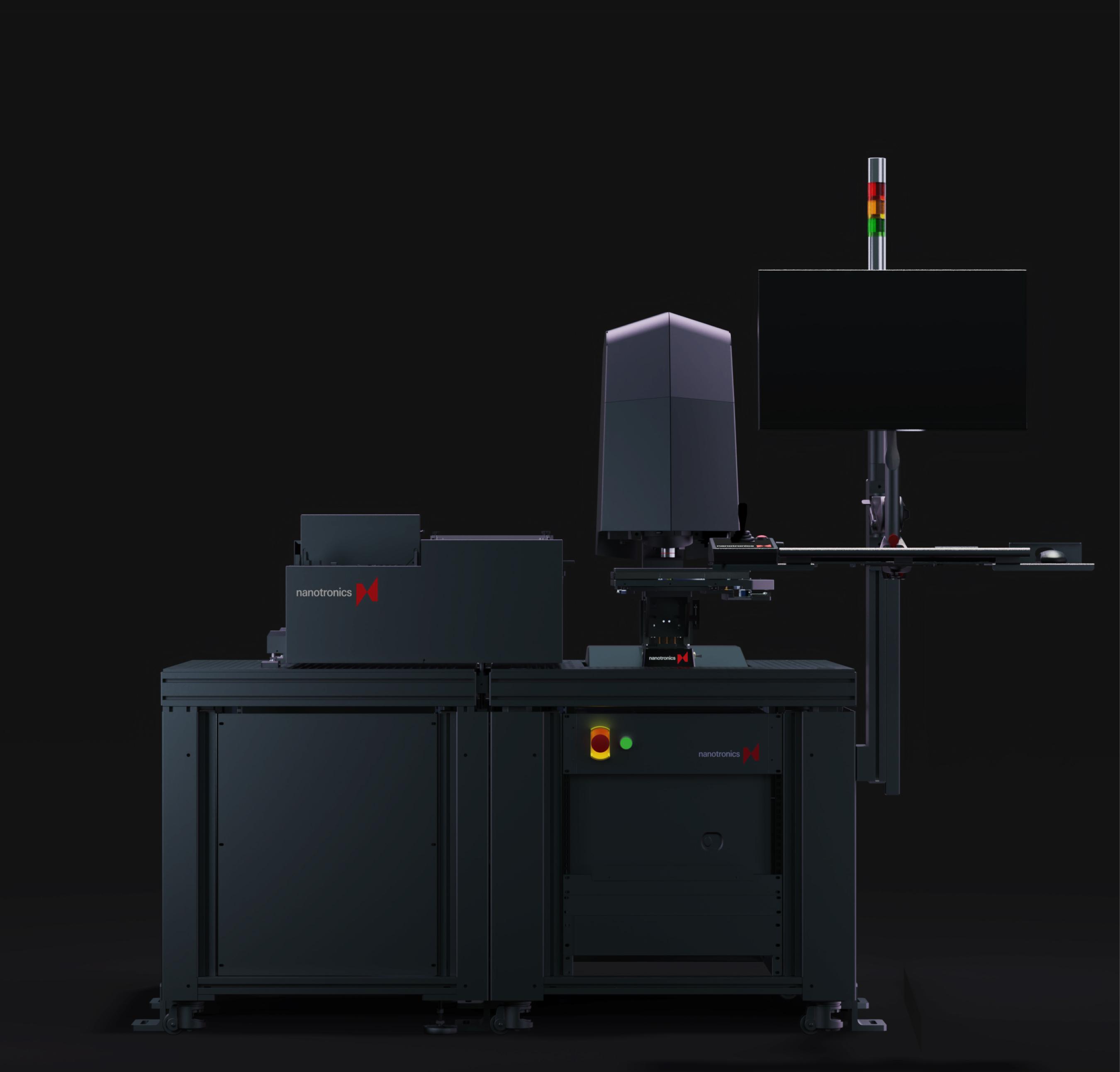

Automated Optical Inspection combined with Autonomous Process Control enables R&D to scale to production for next-generation materials.

nSpec tools use AI algorithms to classify defects and detect anomalies between process steps.

Continuous monitoring of sensors and actuators on the factory floor provides process engineers with the information needed to keep tools performing optimally.

Automate inspection from R&D to production with a single tool

nControl integrates factory sensor and automation data to track, monitor, and improve yields and performance.

Semiconductor manufacturing plants can cost many millions of dollars or billions of dollars to build. However, modular semiconductor plants like CubeFabs by Nanotronics have brought down prices significantly and made starting a semiconductor manufacturing plant more accessible than ever before.

The biggest manufacturer of semiconductors is Taiwan Semiconductor Manufacturing Company, or TSMC, who makes over half of the world's semiconductors. While companies like NVIDIA are bigger by market cap, they only design their chips, but don't manufacture them, which is an important distinction in the world of semiconductor manufacturing.

Yes! There are many semiconductor plants in the US. You can check out a complete list here.

A semiconductor plant physically makes semiconductors. These are known as fabs, which is short for "fabrication facility." Many companies, like NVIDIA and other AI chip companies, only design their chips, choosing to outsource manufacturing to a fab.