Automated Optical Inspection (AOI) refers to the methods, tools, and technologies used to monitor and optimize manufacturing quality control.

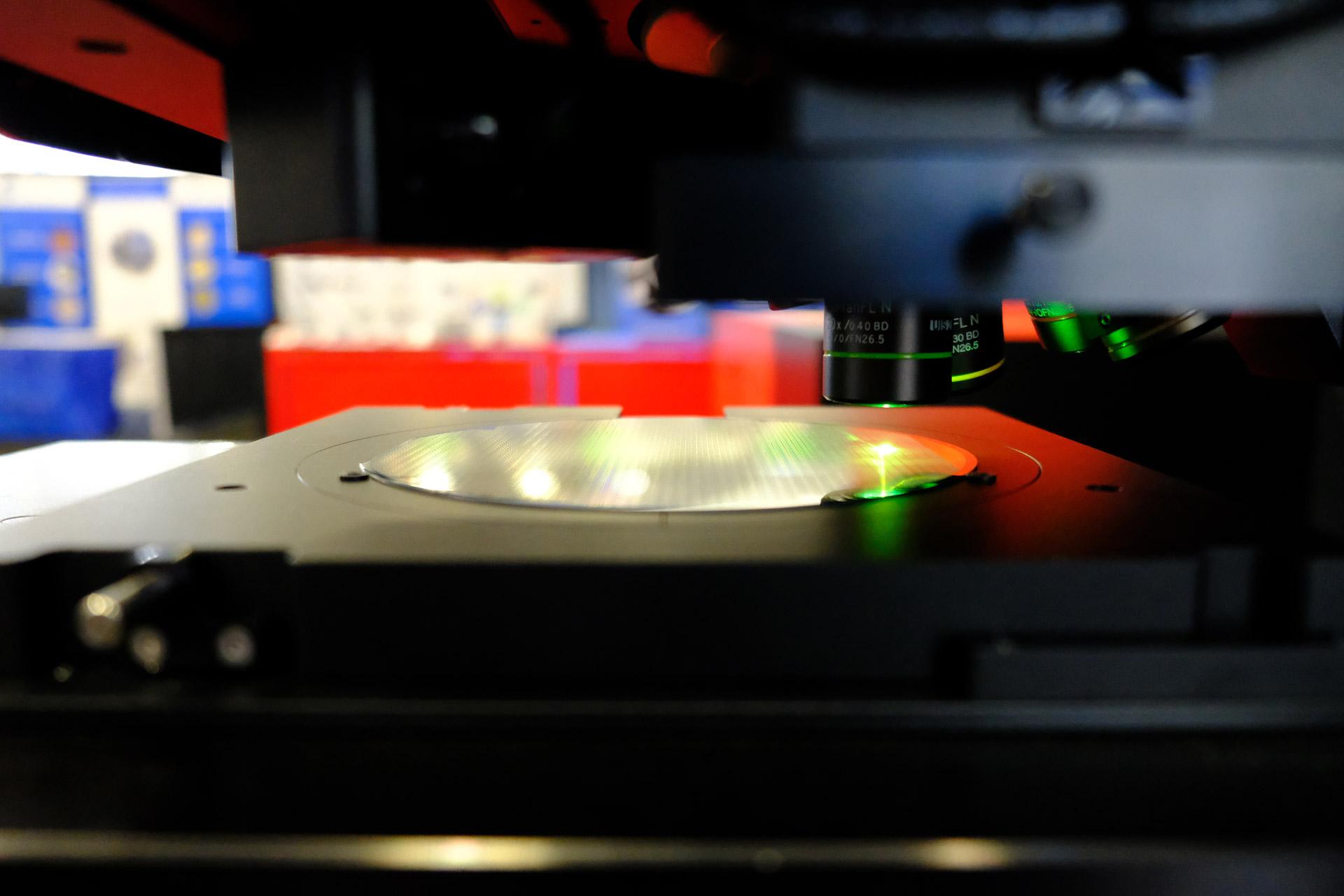

Advanced AOI machines are Automated Optical Inspection systems that utilize integrated software to provide a comprehensive suite of tools for imaging and defect detection. These tools include both hardware and software solutions, and in an industry where the smallest defect can result in major production losses, AOI ensures quality, efficiency, and cost-effectiveness of manufacturing facilities.

Nanotronics has been a leader in the world of AOI for over a decade, but how has AOI evolved in 2025? We've compiled a list of everything you need to know about AOI in 2025. In this article, we’ll explore:

- What is Automated Optical Inspection?

- How Automated Optical Inspection works

- The most effective techniques used

- How businesses can use AOI strategies to optimize manufacturing

What is Automated Optical Inspection (AOI)?

Automated Optical Inspection involves real-time monitoring and assessment of manufactured products to maintain consistency and quality in production. AOI systems are used in everything from electronics assembly to automotive manufacturing. Manufacturing engineers use a combination of advanced cameras, specialized lighting, and sophisticated algorithms to detect and prevent defects before they affect product quality or customer satisfaction.

What is the history of AOI Technology?

Automated Optical Inspection, or AOI, dates back to the 1970s, when the first automated inspection systems were introduced. Initially, these systems used simple cameras and lighting to detect defects on printed circuit boards (PCBs). Over the years, AOI technology has evolved significantly, with advancements in camera resolution, lighting, and image processing algorithms. Today, AOI systems are capable of detecting even the smallest defects and anomalies, making them an essential component of quality control in manufacturing.

Why is AOI important in modern manufacturing?

Automated Optical Inspection (AOI) is a crucial technology used in modern manufacturing to ensure products are free from defects. AOI systems utilize advanced cameras, lighting, and image processing algorithms to analyze components with incredible accuracy. The importance of AOI in modern manufacturing lies in its ability to guarantee impeccable product quality, reduce production costs, and increase efficiency. By detecting defects early in the production process, manufacturers can prevent costly rework, reduce waste, and improve overall product reliability.

How does Automated Optical Inspection work?

We have a deep dive on inspection technologies on our resources page, but simply put, the process involves capturing high-resolution images of products that are then analyzed against a reference with extreme precision. There are multiple steps that all must work together perfectly to create an effective inspection system. Automated optical inspection systems offer advanced capabilities such as high-accuracy inspection and measurement and need to be installed by professionals as any small error can lead to costly problems.

Defect detection and classification algorithms

Defect detection and classification algorithms play a vital role in automated optical inspection systems. Optical inspection is crucial in identifying defects within the manufacturing process. These algorithms analyze the captured images to classify and detect defects with high precision. Integrating AOI systems within the production line is essential to maintain quality control.

Image acquisition and processing techniques

AOI systems may utilize a single or multiple cameras positioned at different angles to capture high-resolution images of the product under inspection. These images are then processed by specialized software that uses intricate algorithms to identify any anomalies or deviations from the expected specifications. The software can differentiate between acceptable variations and actual defects, flagging potential defects for further examination or corrective action. Advanced image processing techniques, such as 3D imaging and machine learning, are also being used to improve the accuracy and efficiency of AOI systems.

What are the most effective AOI techniques for quality control?

Keeping manufacturing quality control running smoothly is all about precision. One missed defect in the inspection process, and suddenly, you’ve got faulty products, customer returns, production headaches, and wasted money. That’s where effective AOI techniques come in. These methods help engineers detect, assess, and verify manufacturing quality in real time—keeping things efficient, consistent, and cost-effective. Advanced systems and technologies support these manufacturing processes to enhance quality control and overall performance. Some common techniques used by engineers to keep their quality control running efficiently are:

- Multi-angle inspection – positioning cameras at various angles across the inspection system to quickly and accurately identify defects from different perspectives.

- Advanced image processing - monitoring manufacturing quality in real time with statistical alerts, automated response protocols, high-resolution imaging, and dashboards for quality managers.

- AI and machine learning – analyzing the inspection data to spot defects that human inspectors might have missed and to predict potential failures before they happen.

These techniques help prevent massive losses in production yield, affecting the efficiency of the factory and leading to a tremendous amount of material and financial waste.

How can businesses harness the power of AOI?

AOI systems are crucial in various industries for maintaining high standards of quality. Among other things, these systems are designed to inspect bare semiconductor wafers and devices on common substrates to ensure high-quality manufacturing. By identifying defects early in the production process, AOI helps in reducing waste and improving overall product quality.

The Bottom Line

Manufacturing inspection is complex, but with the right AOI techniques, companies can reduce defects, increase efficiency, and improve overall product quality. Whether it’s real-time monitoring with advanced image processing, predictive analytics with AI, or comprehensive checks with multi-angle inspection, these techniques ensure that every product meets the highest standards. From assisting the semiconductor manufacturing process to avoid device killing defects to inspecting pharmaceutical packaging, pill coatings, and dosage forms to ensure safety and efficacy, this highlights the critical role of quality assurance in various industries.

Unsure what AOI solutions are right for your business? Click here to schedule a call with one of our experts.