AI Visual Inspection is transforming quality control by providing AI solutions to operators to help them detect anomalies more effectively. While traditional visual inspection methods often rely on manual processes, AI Inspection leverages visual inspection methods with machine learning to make factories more efficient and profitable.

By leveraging artificial intelligence, manufacturers are able to streamline quality control like never before. In this article, we’ll explore what AI inspection is, how it works, and how businesses can use it to improve efficiency and reduce costs.

Table of Contents

- What Is AI Visual Inspection?

- How Can AI Be Used in Visual Perception?

- What Is Automated Visual Inspection?

- What Is Visual AI Testing?

- How Can AI Inspection Help My Business?

1. What Is AI Visual Inspection?

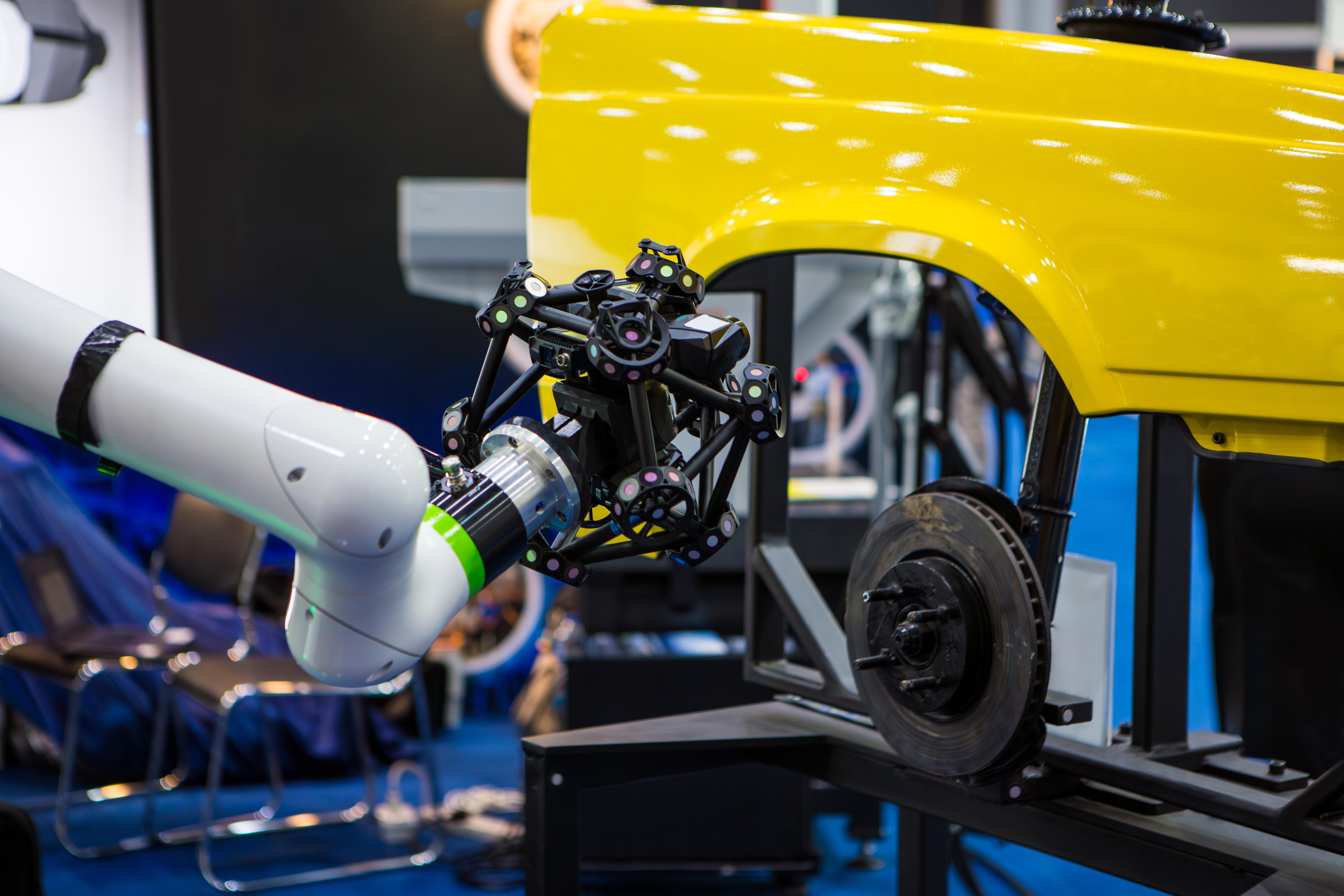

AI visual inspection is the use of artificial intelligence to analyze images, videos, or real-time sensor data to detect defects, irregularities, and inconsistencies in products. Unlike traditional visual inspection methods that depend on human inspectors, AI-powered systems use machine learning and computer vision to identify issues with greater speed and accuracy. AI Inspection allows businesses to maintain higher quality standards while minimizing costs and inefficiencies.

Some Key Benefits of AI Visual Inspection:

- Real-time defect detection – AI-powered cameras and sensors instantly flag anomalies.

- Consistent quality control – Eliminates human error and subjectivity in inspections.

- Scalability – Can inspect thousands of products per minute with precision.

- Cost reduction – Reduces waste and rework by catching defects early.

2. How Can AI Be Used in Visual Perception?

Artificial intelligence mimics human visual perception by using deep learning algorithms to process and interpret images. AI inspection systems analyze patterns, shapes, and textures to identify anomalies in real time. By integrating AI inspection into processes, businesses can achieve greater accuracy and efficiency across a wide range of industries. Some examples of applications of AI in Visual Perception are:

- Object recognition – Identifies components in manufacturing and assembly lines.

- Defect detection – Flags inconsistencies in products, such as scratches or misalignments.

- Predictive maintenance – Detects wear and tear in machinery before failures occur.

- Security & surveillance – Monitors facilities for safety and compliance violations.

3. What Is Automated Visual Inspection?

Automated visual inspection refers to the use of AI and machine vision systems to analyze images, detect defects, and ensure product quality without human intervention. These systems use high-resolution cameras and AI-driven algorithms to perform inspections and diagnose problems faster than their human counterparts. While the technology is complex, the process is simple. AI visual inspection simply consists of:

- Image Capture – High-speed optical cameras take images of products in real time.

- AI Analysis – Machine learning models analyze images for defects.

- Classification & Sorting – Defective products are flagged or removed automatically.

- Continuous Learning – AI models improve over time, increasing accuracy.

4. What Is Visual AI Testing?

Visual AI testing is the process of using AI-powered systems to test and validate the visual quality of products or digital interfaces. AI-based testing can identify very subtle visual defects across multiple environments and conditions faster than traditional, manual methods. By leveraging AI inspection for visual testing, businesses can maintain higher quality standards and improve overall product reliability. Some common uses for Visual AI testing are:

- Manufacturing Quality Control – Detects microscopic defects in semiconductors, electronics, and automotive parts.

- Software & UI Testing – Ensures visual consistency in digital applications across different devices.

- Medical Imaging Analysis – Assists doctors in identifying anomalies in X-rays, MRIs, and CT scans.

5. How Can AI Inspection Help My Business?

AI-powered inspection systems offer a faster, more reliable, and cost-effective alternative to traditional quality control methods. Often times, you don’t even need to buy new hardware - AI Visual Inspection algorithms integrate with your existing equipment. Whether you operate in manufacturing, automotive, healthcare, or software development, implementing AI inspection can significantly improve your operations.

Why Businesses Are Adopting AI Inspection:

- Increases efficiency – Inspects thousands of products per minute with precision.

- Reduces costs – Cuts down on waste, rework, and manual labor expenses.

- Improves product quality – Ensures defects are detected and corrected early.

- Enhances customer satisfaction – Delivers consistently high-quality products to market.

Curious about integrating AI inspection into your business? Contact our team today to learn how AI can enhance your operations.