Semiconductor process control refers to the methods, tools, and technologies used to monitor and optimize semiconductor manufacturing. These tools include both hardware and software solutions, and in an industry where the smallest variation can result in major production losses, process control ensures quality, efficiency, and cost-effectiveness of semiconductor manufacturing facilities.

In this article, we’ll explore:

- What semiconductor process control is

- How semiconductor process control works

- The most effective techniques used

- How businesses can use process control strategies to optimize manufacturing

What is Semiconductor Process Control?

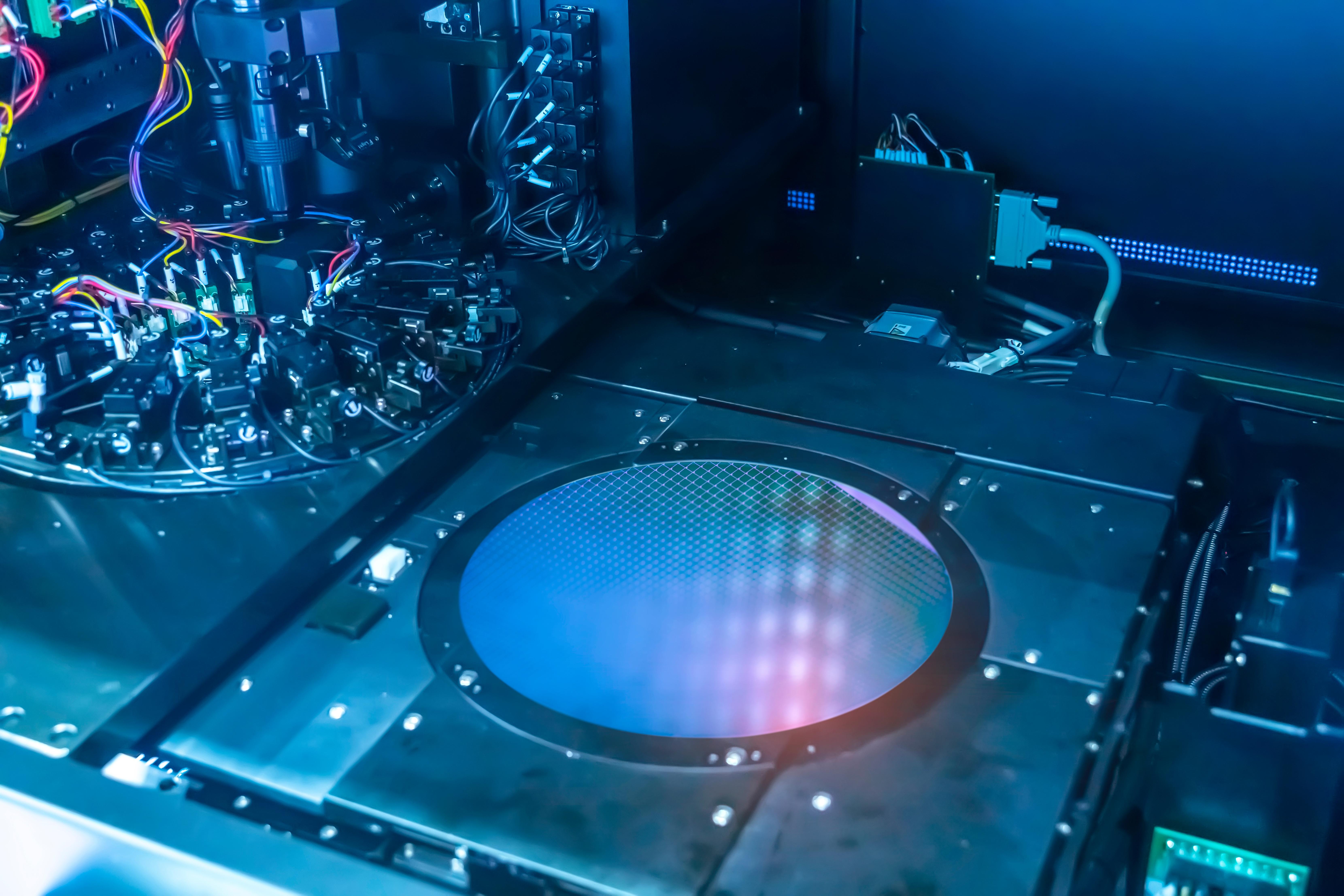

Semiconductor process control involves real-time monitoring and adjustment of manufacturing processes to maintain consistency and quality in semiconductor chip production. These chips are used in everything from smartphones to AI systems, making process control crucial for industries worldwide. Process engineers use a combination of advanced sensors, automation, and artificial intelligence to detect and prevent manufacturing defects before they affect yield.

How does Semiconductor Manufacturing Work?

We have a deep dive on semiconductor manufacturing on our resources page, but simply put, the process involves a series of highly controlled steps designed to fabricate integrated circuits with extreme precision. There are hundreds of steps that all must work together perfectly to create a usable semiconductor and when they are all working well they can create a highly-effective manufacturing line. However, with all the steps involved in making a computer chip, any small error can lead to costly problems. Some common problems are:

- Process drift

- Lithography and overlay control challenges

- Fault detection & classification limitations

- Run-to-Run (RtR) control limitations

- Potential for high costs of process control & automation

What are Effective Process Control Techniques?

Keeping semiconductor manufacturing running smoothly is all about precision. One small variation in the process, and suddenly, you’ve got defective chips, wasted materials, production headaches, and wasted money. That’s where process control techniques come in. These methods help engineers detect, adjust, and fine-tune manufacturing conditions in real time—keeping things efficient, consistent, and cost-effective. Some common techniques used by engineers to keep their manufacturing lines running efficiency are:

- In-line Metrology and Inspection – positioning inspection tools across the manufacturing line to quickly and accurately identify defects.

- Advanced Process Control - Monitoring manufacturing efficiency in real time with statistical alerts, automated response flow checklists, feed-forward control, and dashboards for process managers.

- AI and Machine Learning – analyzing the data gathered from Advanced Process Control to spot defects that human inspectors might have missed and to predict failures before they happen.

These problems can lead to massive losses of yield, affecting the efficiency of the factory and leading to a tremendous amount of material and financial waste.

The Bottom Line

Semiconductor manufacturing is complex, but with the right process control techniques, companies can reduce defects, increase efficiency, and improve overall yield. Whether it’s real-time monitoring with APC, predictive analytics with AI, or quality checks with in-line metrology, these techniques ensure that every chip meets the highest standards.

Unsure what solutions are right for your businesses? Click here to schedule a call with one of our experts.