The First Industrial Revolution represented a great leap in ingenuity that took centuries to evolve, but the period from 1760–1840 marked a defining historical moment—a time of exponential growth that has shaped the modern world as we know it.

That same evolution is taking shape once again as AI and machine learning (ML) lead us toward a new manufacturing paradigm.

We’ll take a brief look at the history of automation in manufacturing, how we have advanced, and what the framework of the past foretells for our near future.

The Advent of Automation in Manufacturing

Thousands of years before the Industrial Revolution, the water wheel was created for automating irrigation and milling grain, eventually serving as a source of electricity. This fairly rudimentary technology acted as a portent for the future of automation, and we have adopted new ways of building and thinking about tech that stem from its early applications.

1700s–1800s

Innovations like steam power and textile machines brought a radical acceleration to productivity, resulting in:

- Steam-powered hydraulic and pneumatic systems

- New forms of transportation

- Increased wealth

- Emergence of industrial clusters

These are early examples of process automation: implementing systems to improve efficiency, reduce costs and errors, and boost productivity.

1900s: The Birth of Modern Manufacturing

In 1913, the Ford Motor Company made substantial contributions to the history of automation in manufacturing with the introduction of Henry Ford’s assembly line process, eponymously known as “Fordism,” by reducing the production time of the Model T down from 12 hours to only one and a half hours per vehicle.

The Evolution of Automation

Industry continued to advance at a rapid pace well into the 20th century. The following innovations illustrate gradual progression toward the exponential growth we are witnessing today.

US Military Manufacturing

World War II brought innovation out of necessity, inspiring the automation of production and assembly for military fighter airplanes, landing crafts, warships, and tanks.

Japan’s Economic Miracle

Post-war Japan suffered years of economic stagnation, but their advances in automobile manufacturing from the late 1940s through the 1960s were equally as influential as Henry Ford’s breakthroughs.

By introducing W. Edwards Deming’s theory of management into the factory, companies like Honda, Toyota, and Nissan improved the quality and reliability of their final products—insight we still draw from in designing today’s quality control tools.

Industrial Robots

In the 1960s, companies such as General Electric, Hitachi, and Kawasaki deployed industrial robots to automate specific, repetitive tasks.

Computer-Aided Design (CAD)

In the 1970s, CAD and Computer-aided manufacturing (CAM) introduced innovative software-based solutions to assembly procedures that radically changed how products were designed and produced.

The Computational Revolution

The 1980s into the 1990s saw one of the most significant leaps forward within the history of automation in manufacturing. The ability to fit more transistors onto smaller semiconductor chips accelerated microprocessor capabilities, and the introduction of computing power into the factory revolutionized management structure at every level of operation, from the assembly line to office administration.

The personal computer’s impact on the history of automation in the workplace had only one rival of magnitude: the internet. Every facet of a manufacturing organization can now be connected and optimized via edge networking, from supply chain and inventory to shipping routes, sourcing, client management, and retail.

2000s: The Age of Automation and AI

The first two decades of the 21st century were marked by extreme growth. Within domestic spaces, we have grown accustomed to robots that clean our floors, and redundant warehousing tasks are now managed using AI-backed inventory management tools. It stands to reason that other trends following a similar trajectory will become the norm, including the following robotic and autonomous AI-based tasks and roles:

- Self-driving vehicles

- Surgical procedures

- Landscaping

- Customer support

- Janitorial services

- Fast food services

- Welding

- Telemarketing

Breakthroughs in several key areas have greatly boosted process automation.

Robotic Process Automation (RPA)

RPA involves automating repetitive data entry, customer service, and other software-based processes.

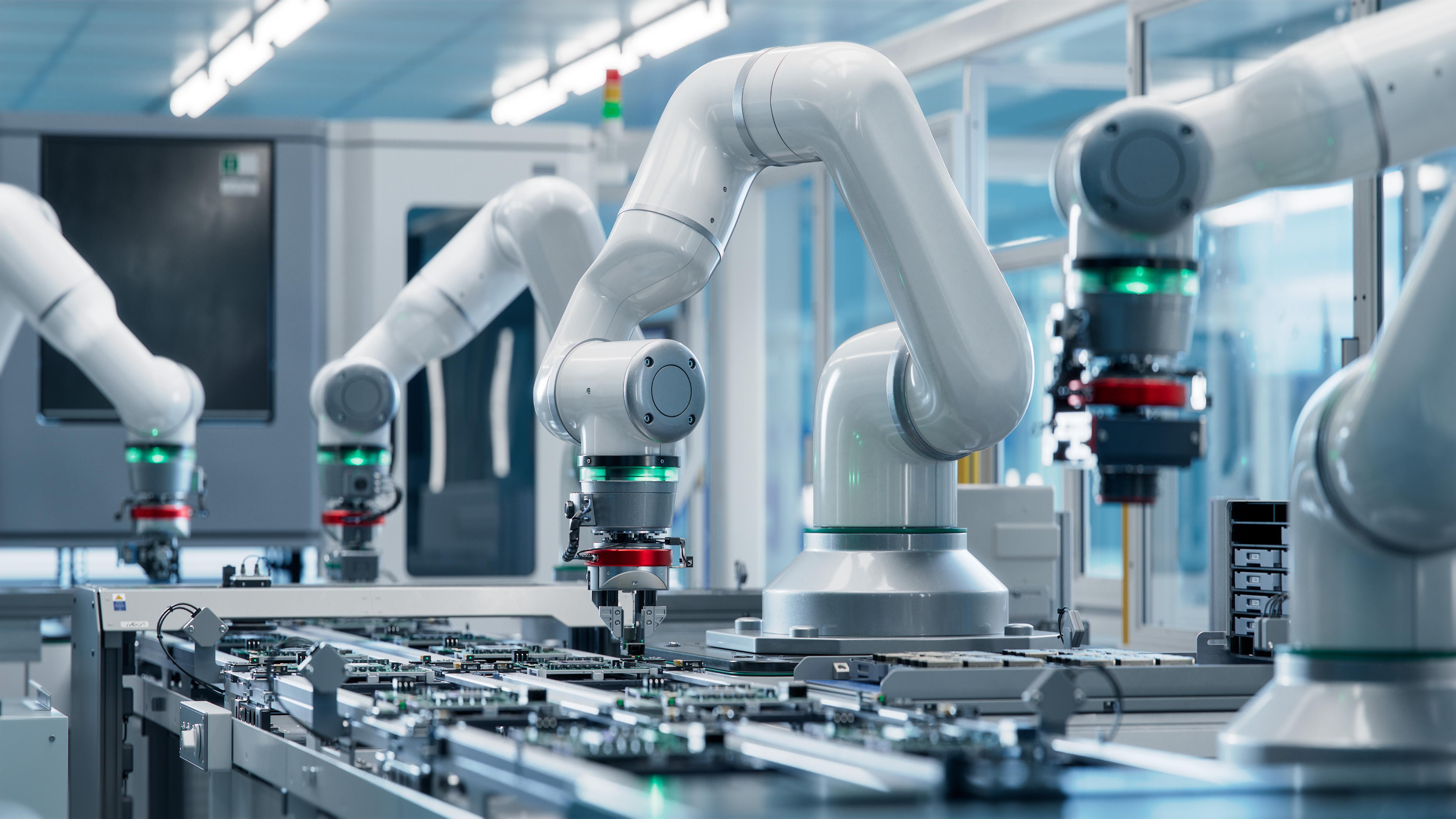

Automated Robotics

Physical robots have the accuracy, efficiency, and cost-saving functions to dramatically scale their use across numerous stages of manufacturing.

Sensors

Sensors correlate processes, movement, vibration, and other data streams with sophisticated algorithms gathering metrics and monitoring for everything from maintenance alerts to points of potential optimization.

Predictive Maintenance

AI and ML can anticipate the ideal moment to save on costs and reduce downtime by predicting future errors in process, and identifies when and what needs to be replaced to maintain factory equipment.

Inventory Management

AI and ML assist in managing inventory, shipping, orders, and accounting without human intervention.

Optical Microscopy

The precision and advancement of AI and ML make it possible to perform cutting-edge analysis on defects and contaminants down to the nanoparticle, with the ability to train software to continually augment its pattern recognition database.

The Internet of Things (IoT)

When computers, robotics, sensors, AI, and ML are consolidated into a singular system, a new sector of radical change emerges in the form of smart devices. These devices are connected to the internet for purposes of data exchange, upgrades, and optimization.

2020s and Beyond: Uncertainty and Hope

We are entering an era in which unprecedented advancements in AI are paving the way for complete automation in every sector of society, including much of the modern workforce. This leads to some trepidation about whether the state of technology has gained too much momentum to control.

While we speculate about this great unknown, many beneficial applications are likely to merge with one another as they evolve into their next iteration.

Smart Cities

As IoT progresses and becomes increasingly cost-effective, every aspect of modern cities is connected to automated databases that monitor information circulation and optimize every element of metropolitan infrastructure.

Autonomous Vehicles

Automotive manufacturing, novel supply chain models, and commute routines coalesce to bring about new standards of mobility as self-driving cars are widely adopted.

Cloud-Computing

Local infrastructure is integrated into edge computing data centers that feed information to centralized cloud servers, managing the daily operations of commerce and myriad logistical elements of futuristic urban centers.

The Future of Manufacturing

If you’re looking for the best ways to increase factory efficiency while reducing costs, Nanotronics provides the world’s most advanced AI- and ML-based detection systems to reduce errors and improve product yield.

Get in touch with us to discuss your needs today.