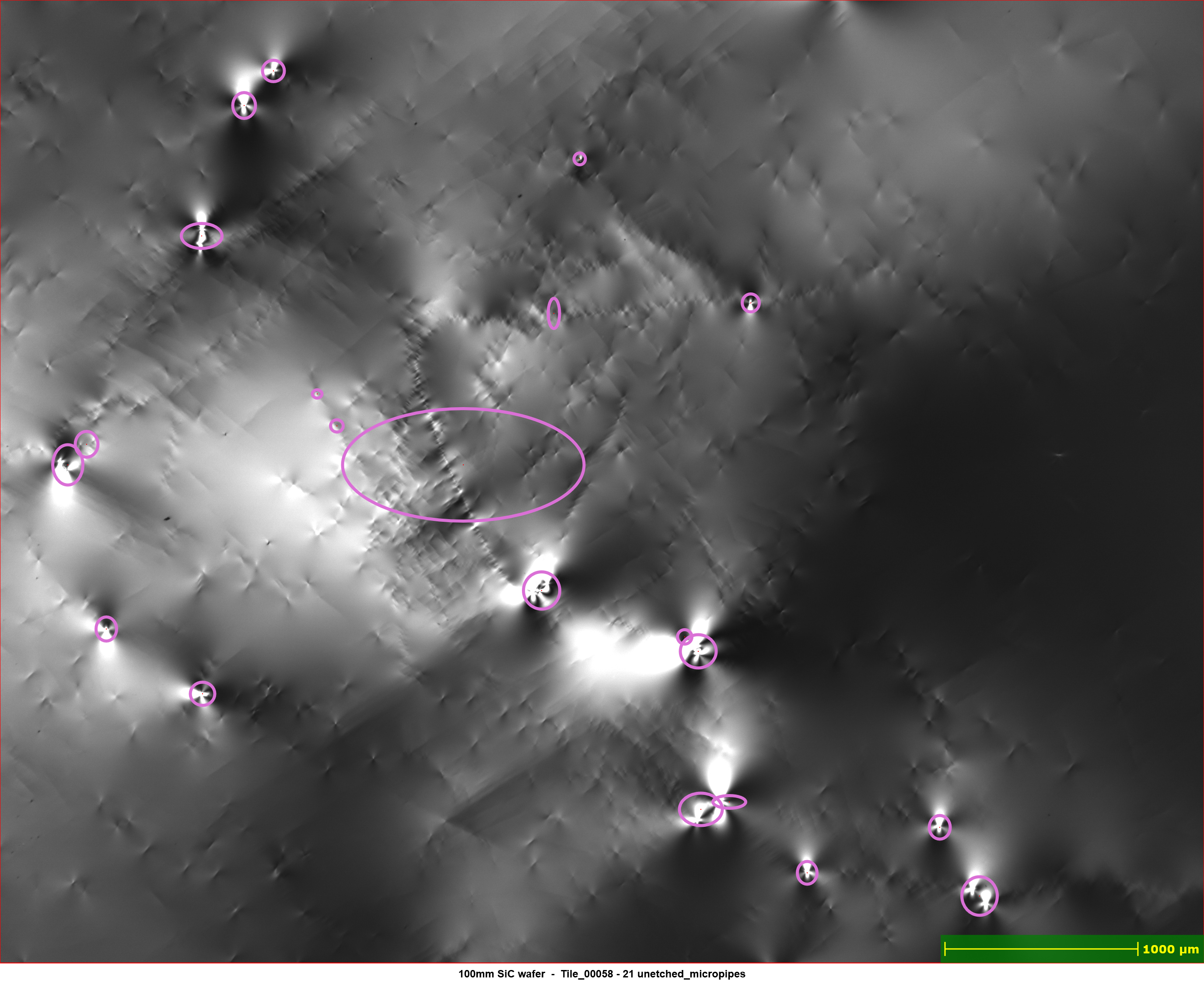

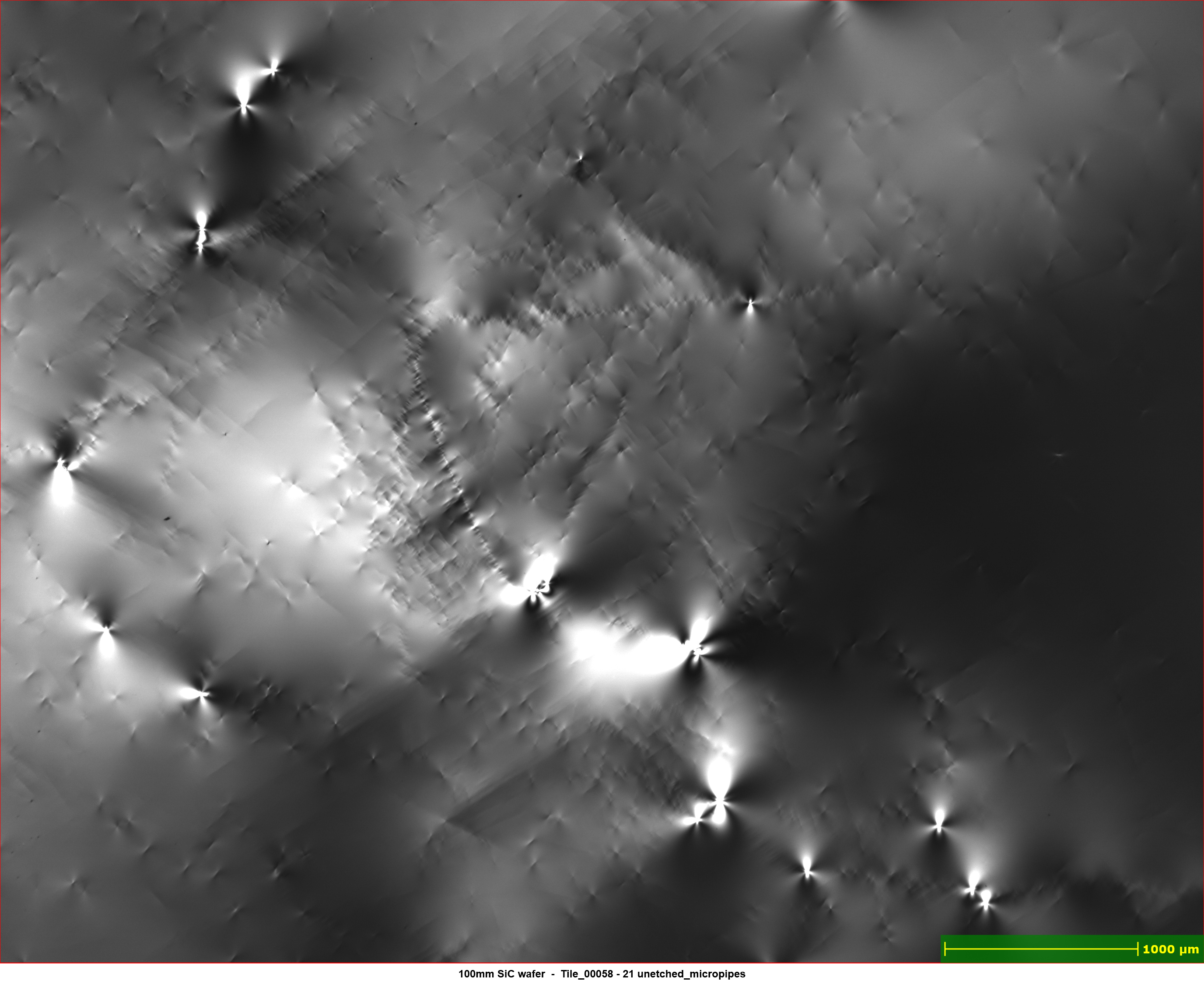

Traditionally, silicon carbide manufacturers identified dislocation-type defects like micropipes using etched wafers—a laborious, destructive process.

Nanotronics’ patented autofocus algorithms combined with cross-polarized transmitted light and DIC (Differential Interference Contrast) illumination replace such manufacturing processes.

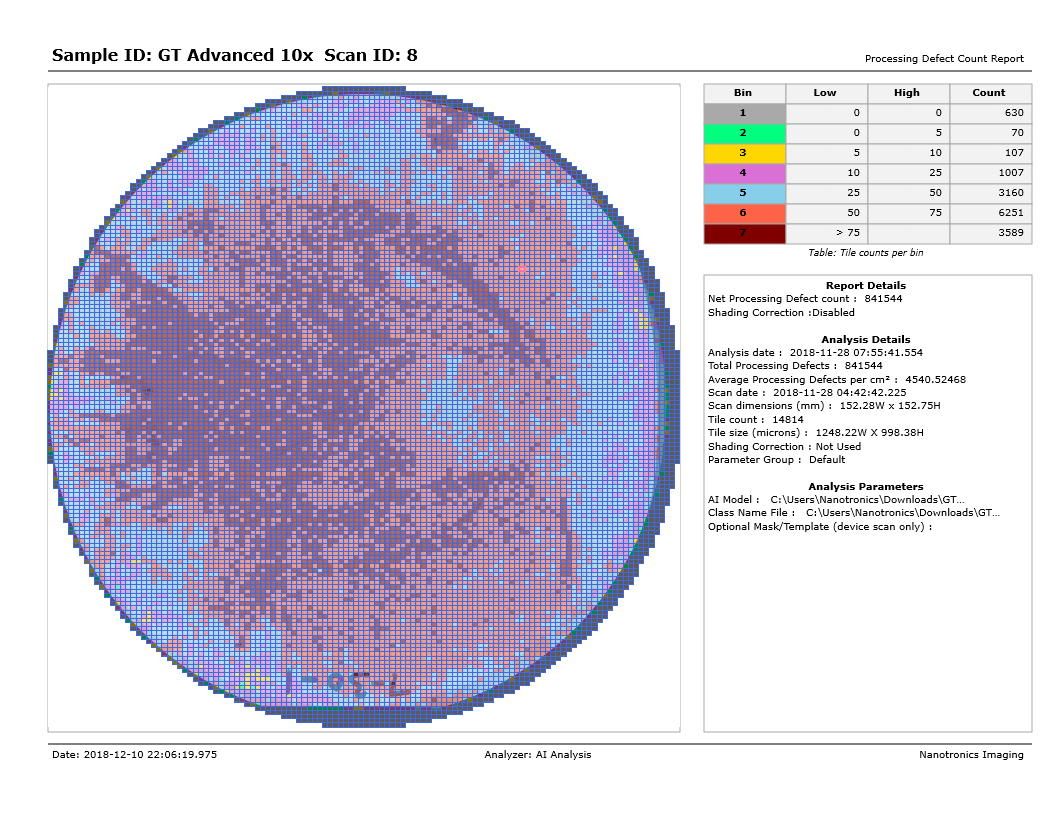

AI classification that detects these subtle, crystallographic substrate defects can be used in-line to provide real-time feedback.

Finally, AI analysis allows the manufacturer to quickly assign causality and differentiate between nuisance and device-killing defects.