Inspection equipment refers to the tools and instruments used by inspectors to collect data. While inspection equipment is present in a wide array of industries, it is incredibly important in semiconductor manufacturing. On the manufacturing line, one small defect can lead to a significant loss of yield, costing businesses time and money. In this article, we will discuss different types of inspection equipment so you can make the best purchasing choices for your company.

What Is Inspection Equipment?

Inspection equipment helps inspectors collect data on their products and is used across many industries. An inspector can be a construction worker using a level to check the horizontal alignment of a shelf or a process engineer using an optical microscope designed to inspect flaws in computer chips. Inspection equipment can be used to investigate defects across a wide variety of products, surfaces, and materials.

While many tools can enhance the efficiency of your operation, we suggest optical inspection. In the following sections, we will explain how optical inspection equipment can help increase your yields quickly, allowing you to focus on other pressing issues.

What Equipment Is Used for Inspection in Semiconductor Manufacturing?

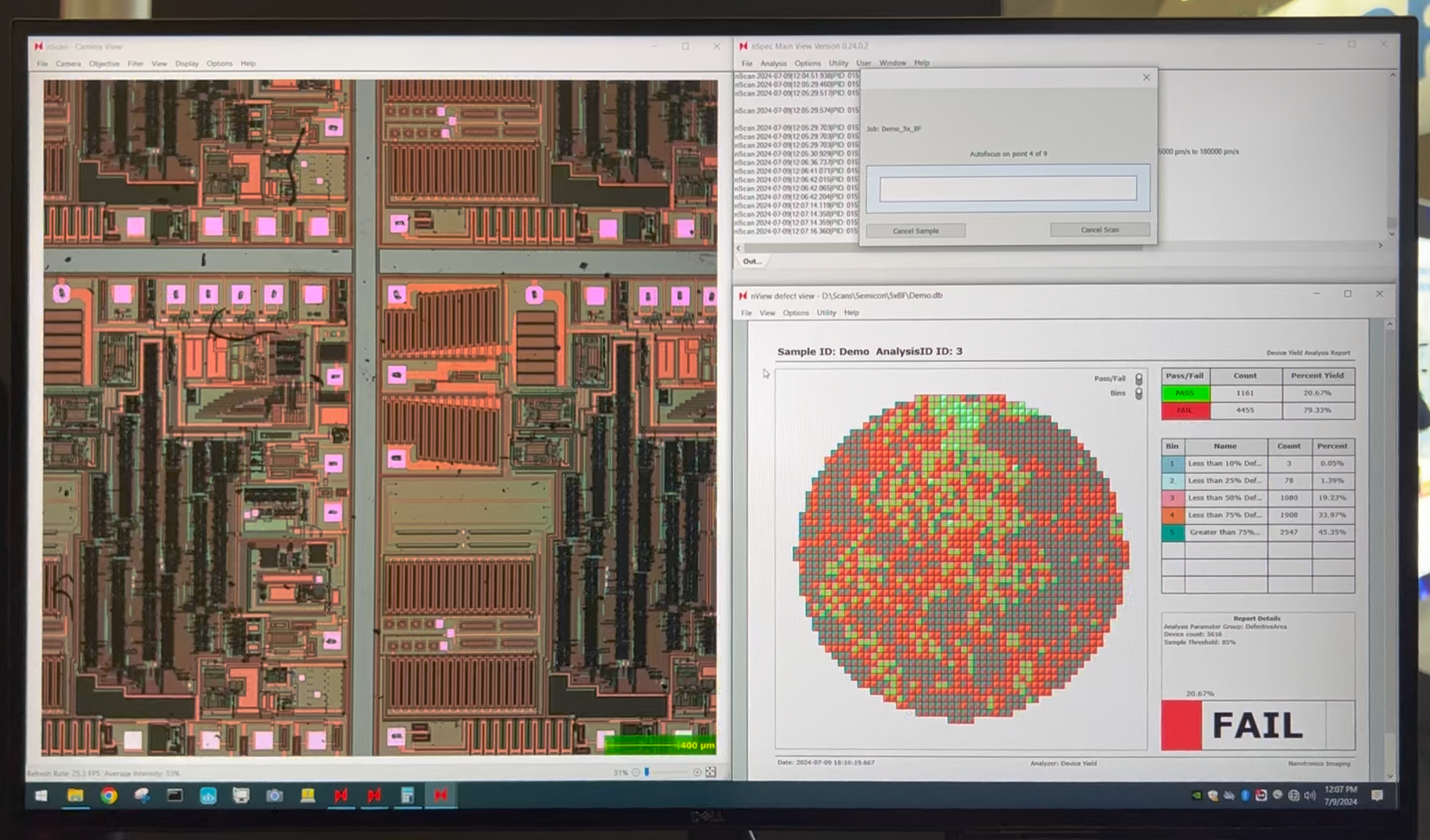

Generally speaking, when process engineers inspect a problem in a semiconductor manufacturing plant, also known as a "fab" or "foundry", they rely on a variety of inspection tools to help them identify the issue. Problems are often discovered through a combination of visual inspection by the engineer, optical or laser inspection using a specialized microscope, and defect classification by AI software.

Problems in semiconductor manufacturing can be costly for companies. They can lead to decreased yields, material waste, lost manufacturing time, and delays on other projects when engineers need to be reassigned to identify a manufacturing issue. While semiconductor manufacturing problems are often complex, unique, and expensive, recent breakthroughs in manufacturing equipment have made these problems solvable through customizable hardware and software solutions—at a lower cost than ever before.

What Inspection Equipment Should I Use in My Semiconductor Manufacturing Facility?

Semiconductor manufacturing plants use a variety of tools to solve production problems. While laser inspection is very effective, recent advances in optical inspection technology make it the first choice for process engineers looking to detect anomalies and fix them—fast. Process engineers prioritize optical inspection solutions because:

- Optical inspection tools can identify most defects that arise in semiconductor manufacturing.

- These tools can be integrated into existing manufacturing lines, minimizing downtime.

- Optical inspection tools are more affordable than laser inspection.

- Optical inspection microscopes can be augmented with AI inspection tools to enhance efficiency and increase yields faster.

- AI defect identification software can be paired with existing optical inspection microscopes, providing a robust, cost-effective solution for identifying defects in semiconductor manufacturing.

What Inspection Tools Are Right for My Business?

While each business has its own unique set of challenges, optical inspection provides robust and customizable solutions to semiconductor manufacturing problems, helping your business stay operational at various price points.

To learn more, click here to speak with one of our experts about how optical inspection equipment can help your business.